Sliding contact principle of Sliding Guide Shoe

As an important mechanical component, the sliding contact principle of Sliding Guide Shoe is an important basis for ensuring the stability and safety of the equipment. Sliding guide shoes realize the guiding and supporting functions through sliding contact with the guide rails, and are widely used in transportation equipment such as elevators and high-speed trains.

1. Structural composition

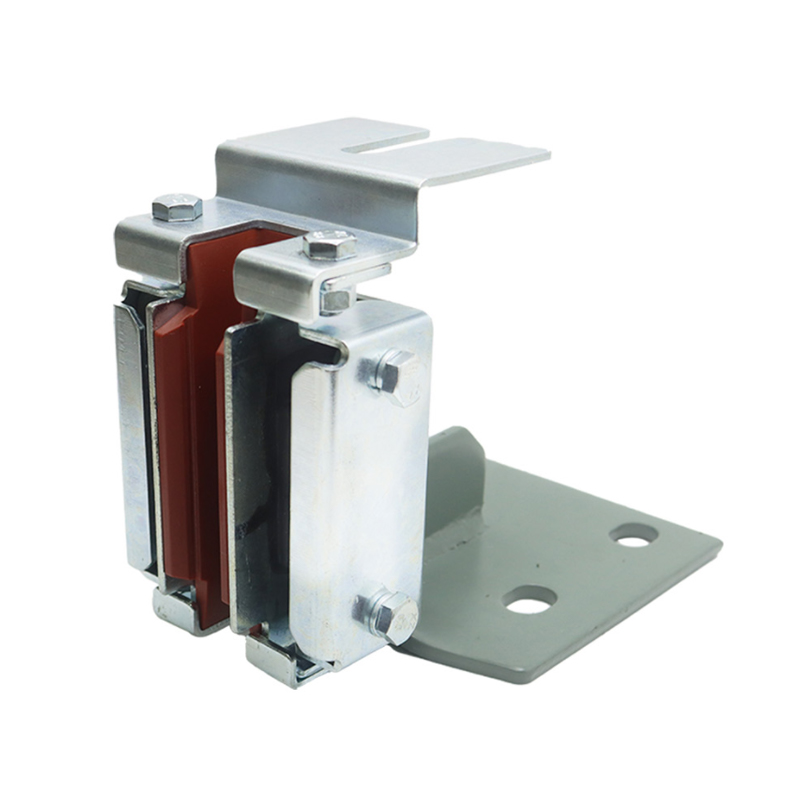

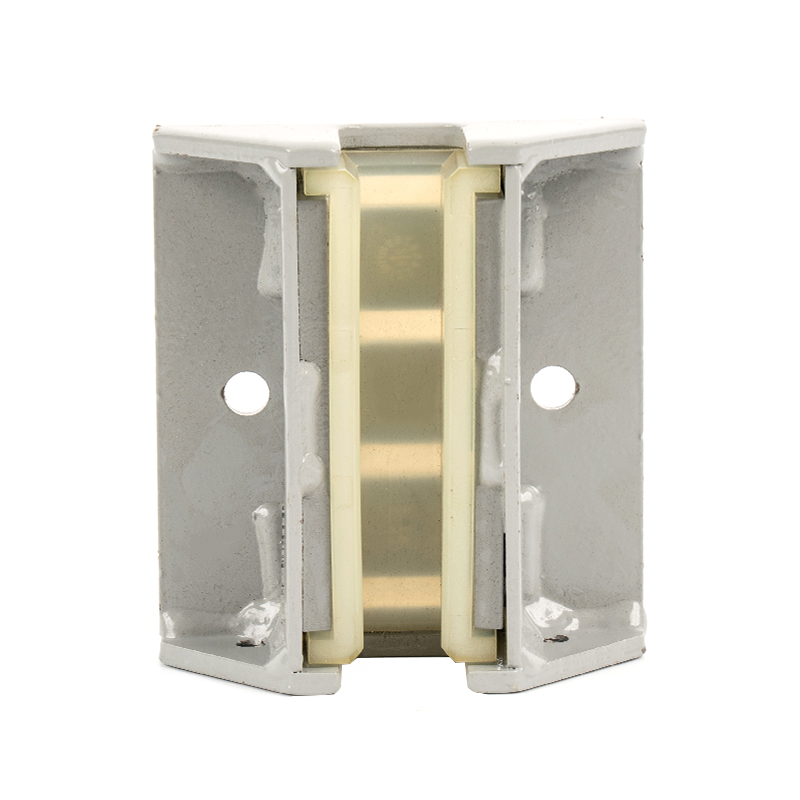

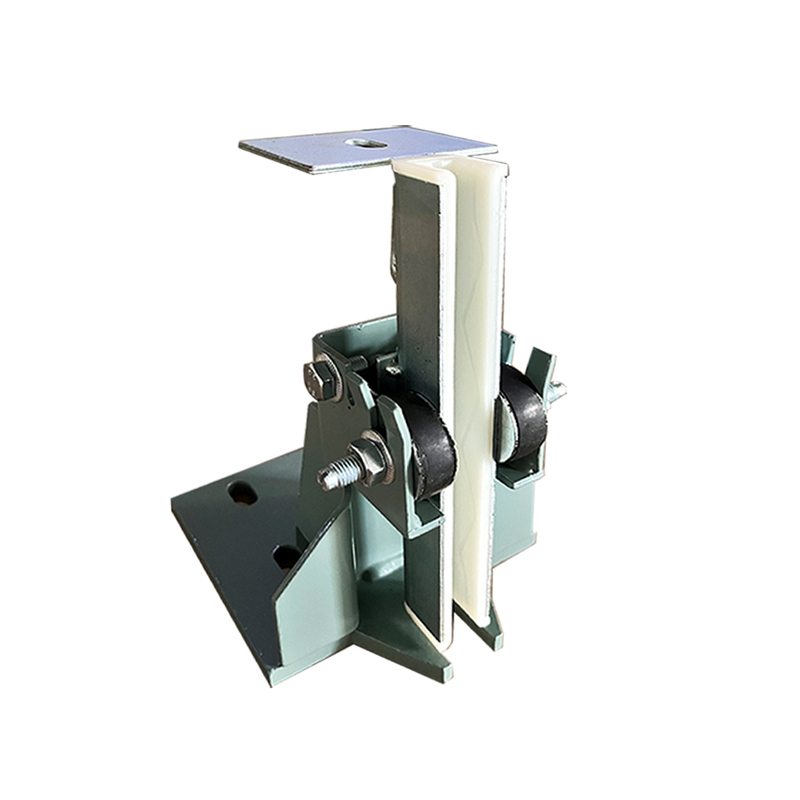

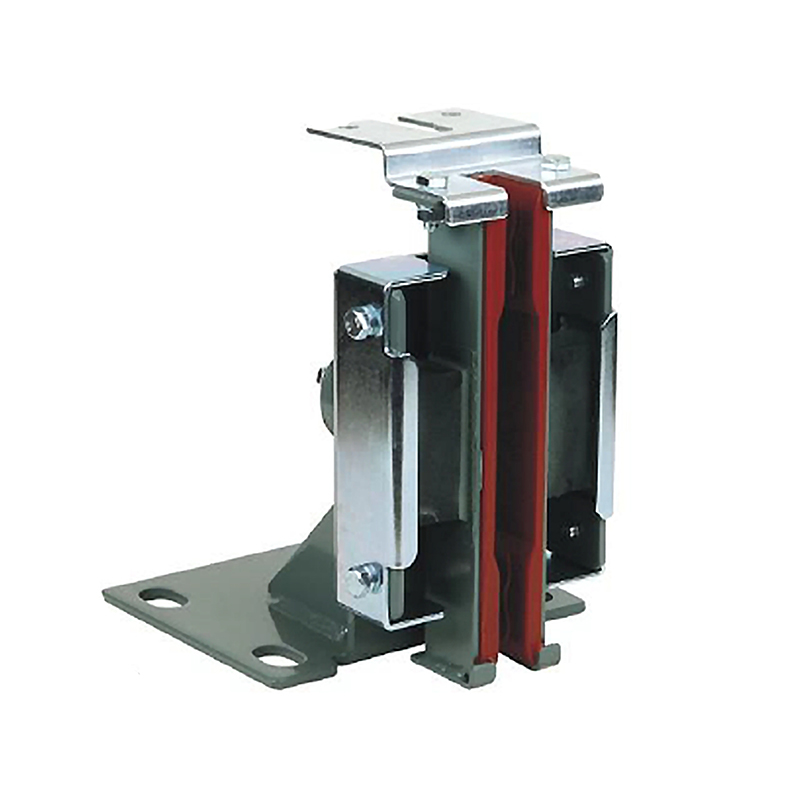

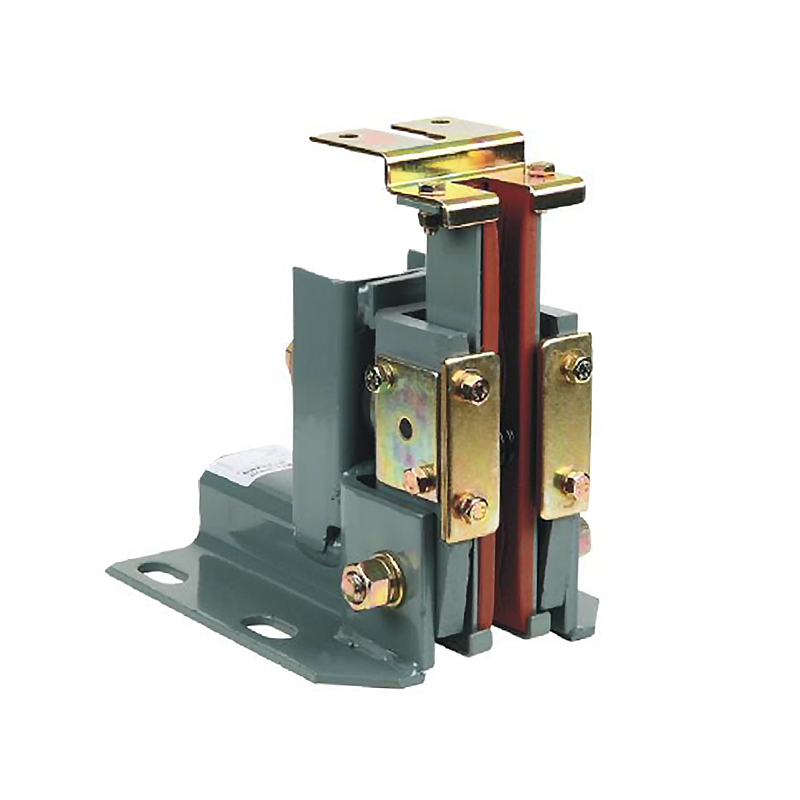

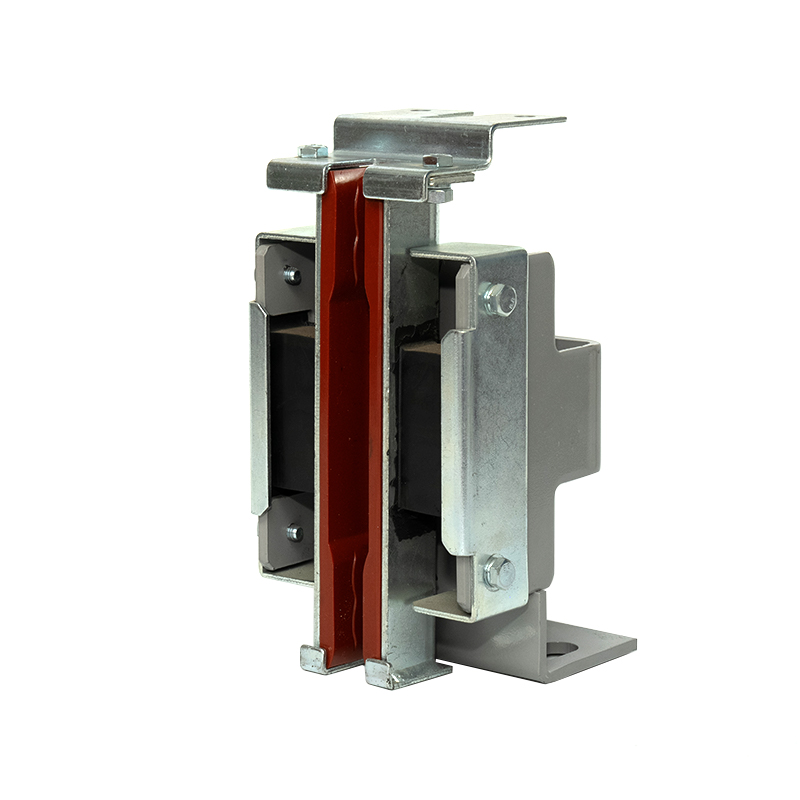

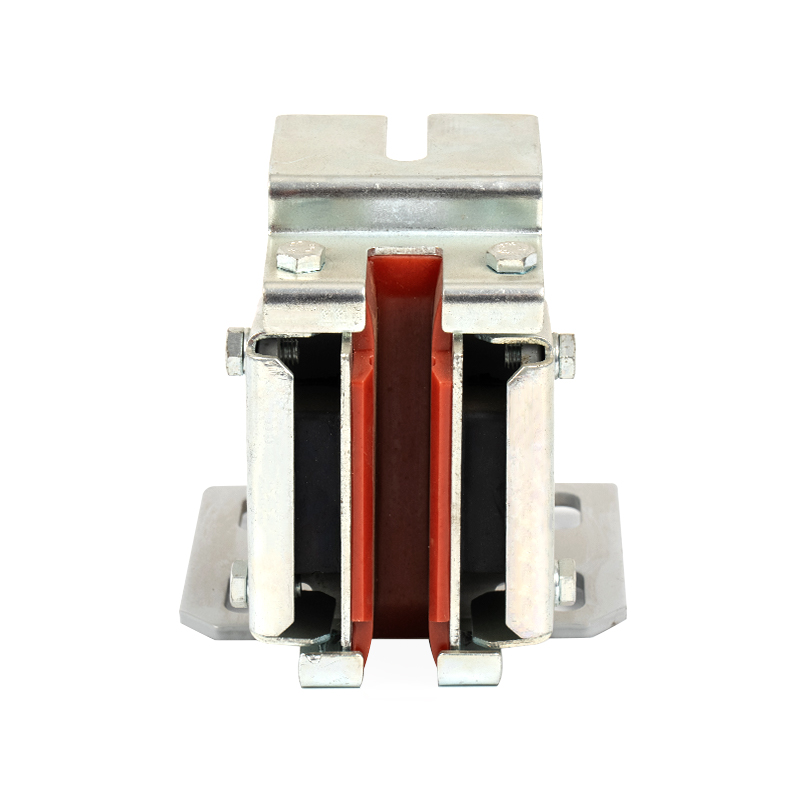

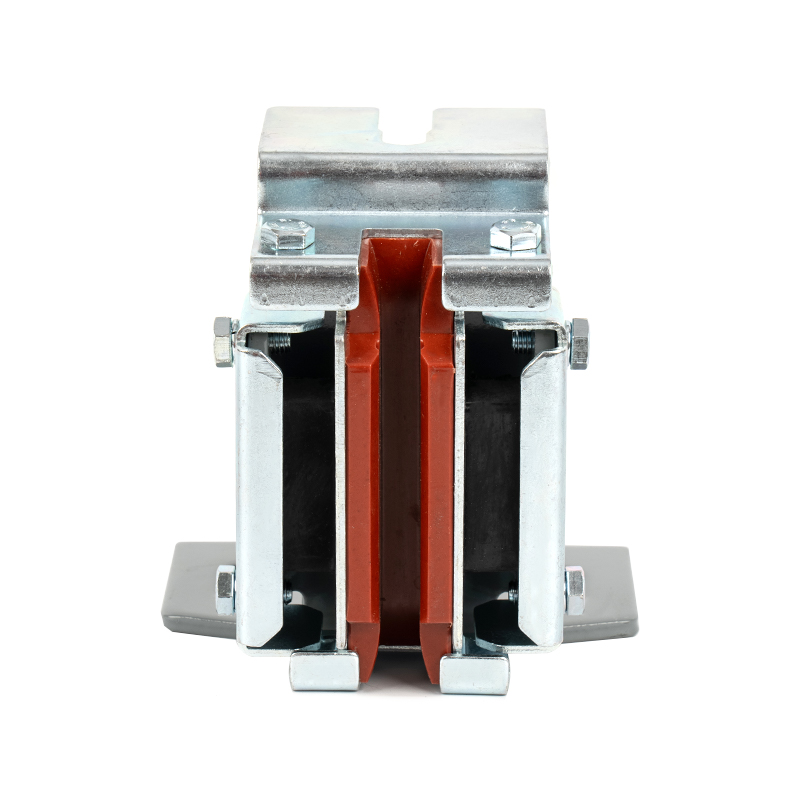

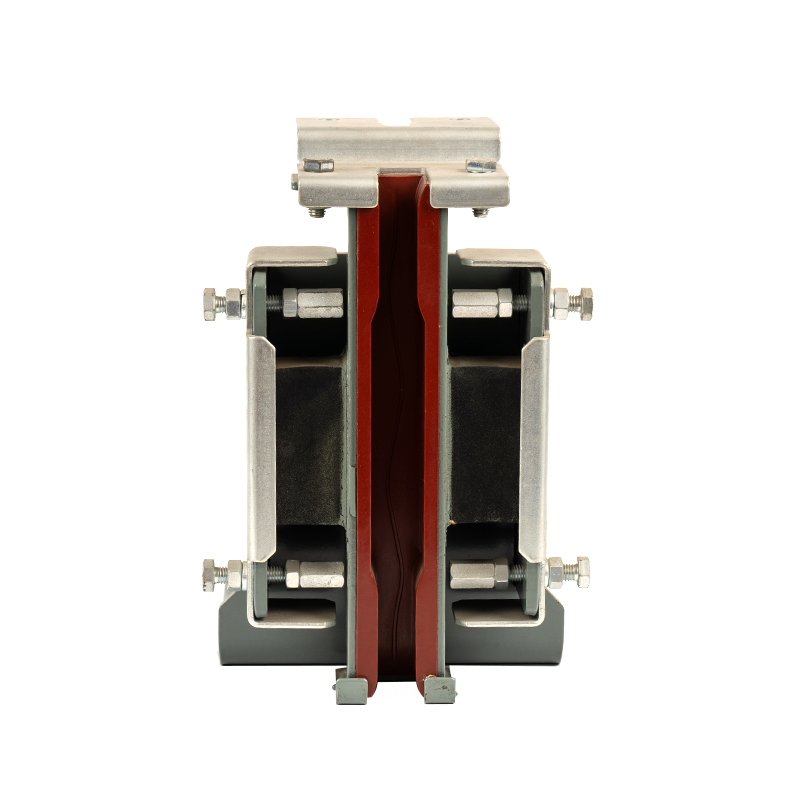

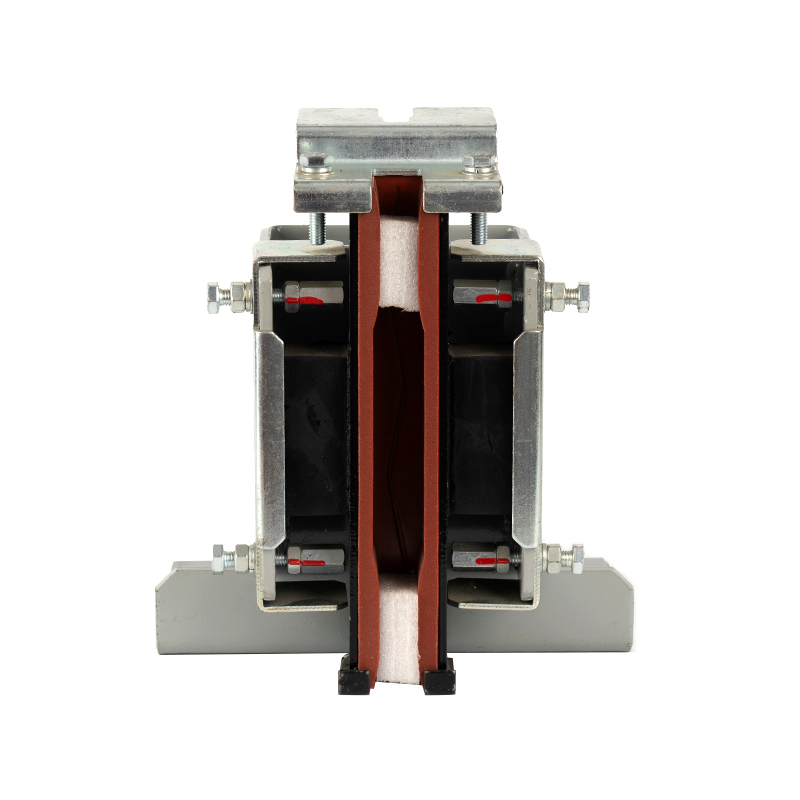

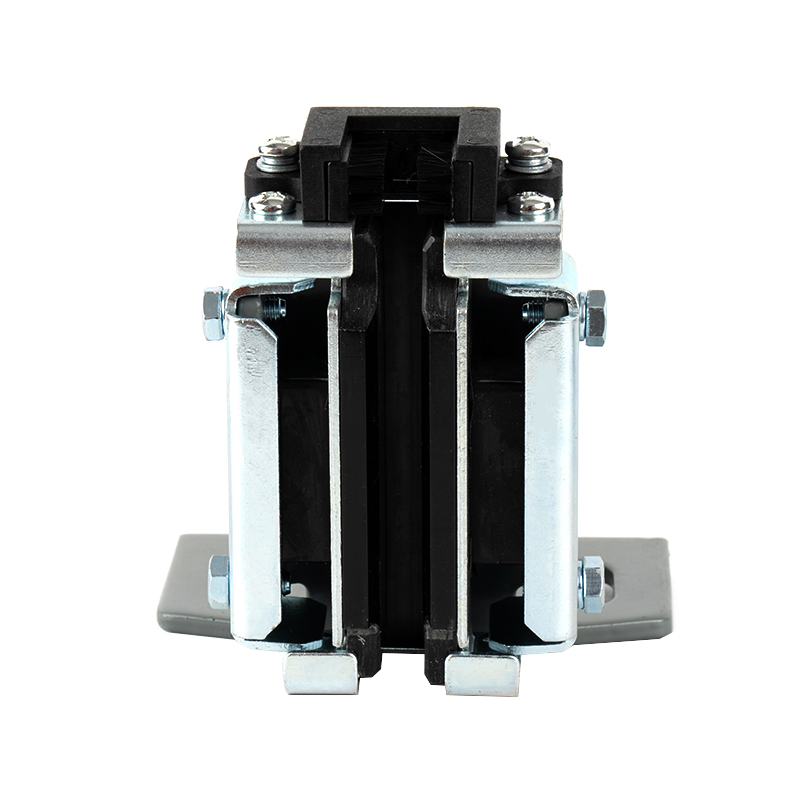

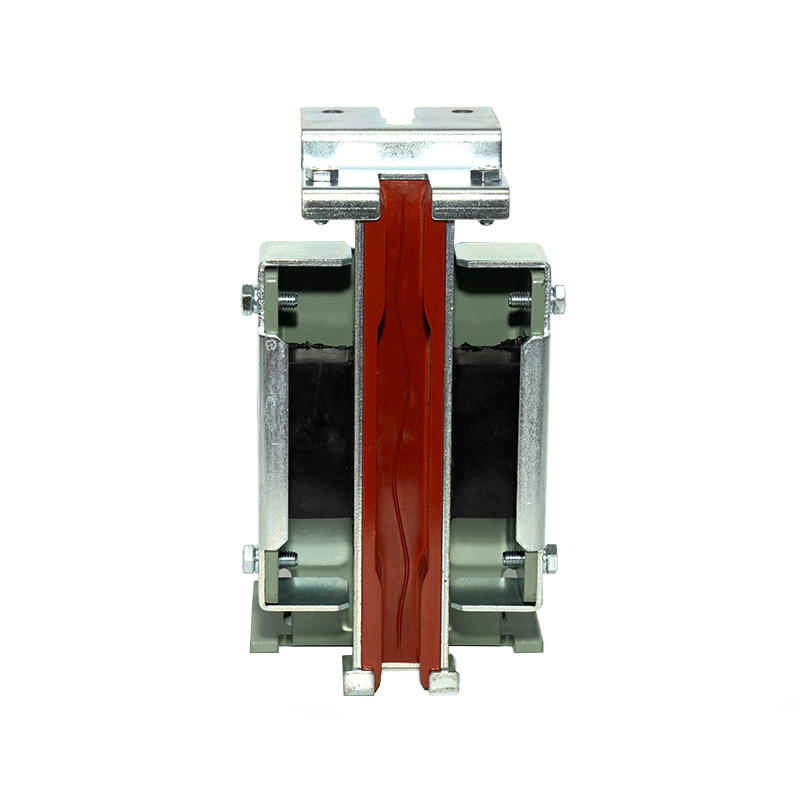

The sliding guide shoe is mainly composed of three parts: toe cap, shoe body and shoe seat:

Toe cap: responsible for guiding and supporting, ensuring that the sliding guide shoe moves smoothly along the guide rail.

Shoe body: bears and transmits the force and torque from the slide rail.

Shoe seat: fixes the sliding guide shoe on the equipment chassis to ensure that it does not move during operation.

The reasonable design of these structures provides a good foundation for sliding contact.

2. Basic principle of sliding contact

The sliding contact principle of the sliding guide shoe is mainly reflected in the friction behavior between the guide shoe and the guide rail. During the sliding process, the toe cap of the guide shoe forms a sliding contact surface with the surface of the guide rail, and the nature of the contact directly affects the operating performance and durability of the guide shoe.

Friction: Friction is the key factor affecting the movement of the guide shoe during sliding contact. An appropriate friction coefficient can provide the necessary grip to prevent the guide shoe from slipping under load. Excessive friction will lead to increased energy consumption and increased wear, so it is crucial to choose the right material and surface treatment process.

Sliding contact method: Sliding guide shoes usually adopt point contact or line contact, depending on the specific requirements of the design. Point contact is suitable for light load or low speed applications, while line contact is more suitable for high load or high speed occasions, which can effectively disperse stress and reduce wear.

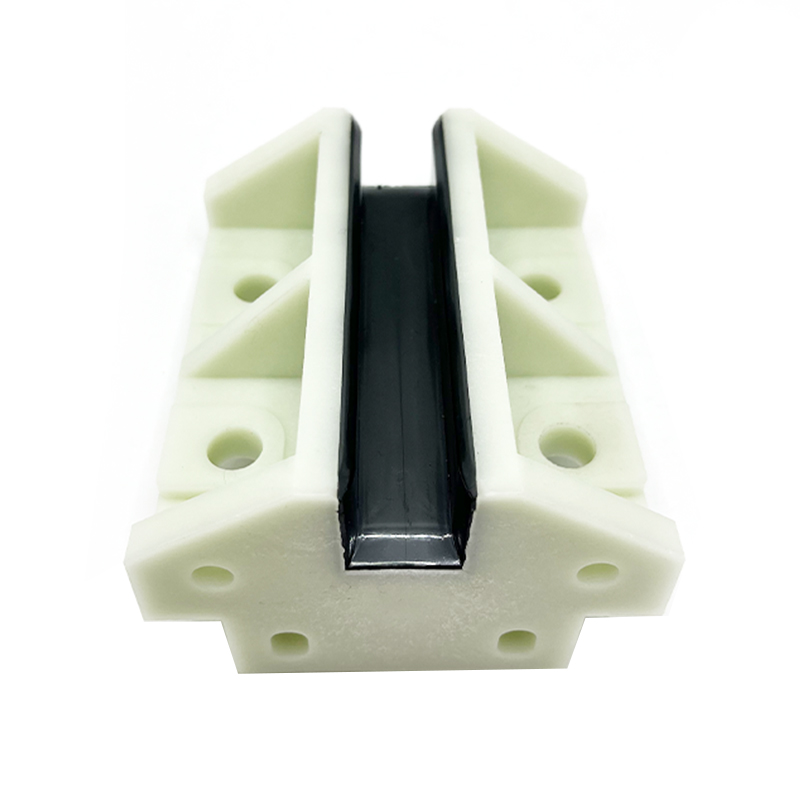

3. Materials and surface treatment

The material selection and surface treatment of sliding guide shoes have a significant impact on the performance of sliding contact. High-strength, wear-resistant materials (such as alloys or engineering plastics) are usually used to manufacture sliding guide shoes. Surface treatment (such as spraying or heat treatment) can further enhance the wear resistance and corrosion resistance of the contact surface, thereby increasing the service life of the guide shoe.

In Ningbo Yinzhou Fukangda Elevator Parts Factory, advanced processing equipment and processes are used to ensure that the materials and surface treatment of sliding guide shoes meet strict quality standards. These measures effectively reduce the friction and wear generated during the sliding contact process and improve the overall performance of the guide shoe.

4. Load transfer during operation

In actual applications, the sliding guide shoe bears the dynamic load from the elevator car or train body. During the sliding contact process, the shoe body is responsible for transferring these forces and torques to the guide rail to achieve stable movement. During this process, the sliding guide shoe must maintain a good contact state to ensure uniform force distribution and prevent safety hazards caused by poor contact.

5. Maintenance and monitoring of sliding contact

In order to ensure the normal operation of the sliding guide shoe, regular maintenance and monitoring are essential. Elevator systems are usually equipped with monitoring devices to monitor the status of the sliding guide shoe in real time, including wear and operating temperature. Once an abnormality is found, the system will issue an alarm to prompt maintenance or replacement. Through these measures, the failure of the sliding guide shoe caused by excessive wear can be effectively prevented, thereby ensuring the safe operation of the elevator.

English

English 中文简体

中文简体