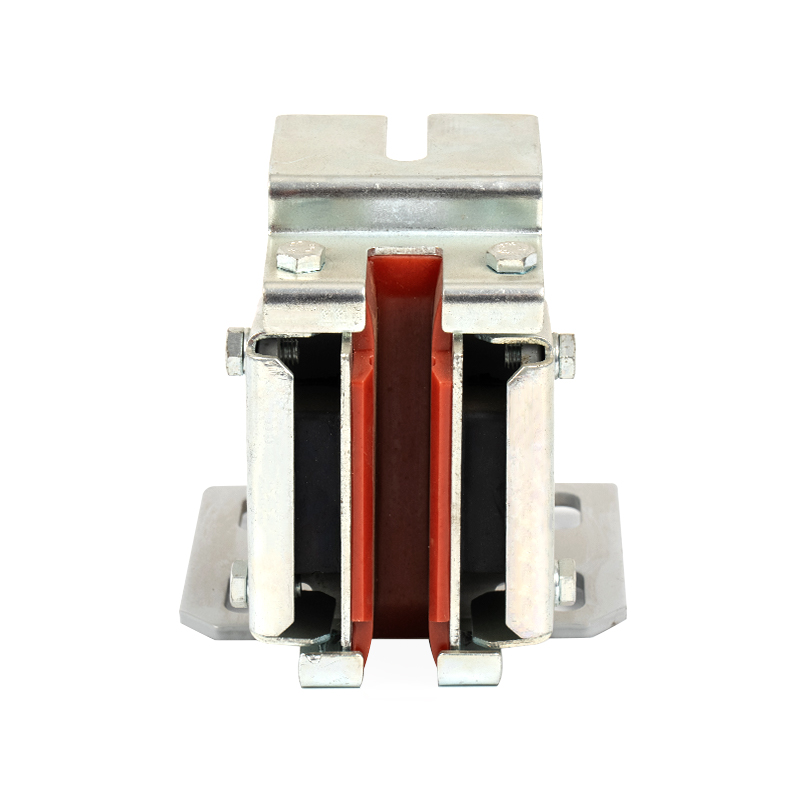

The performance of the wear resistance of the Roller Guide Shoe in long-term high-load operation

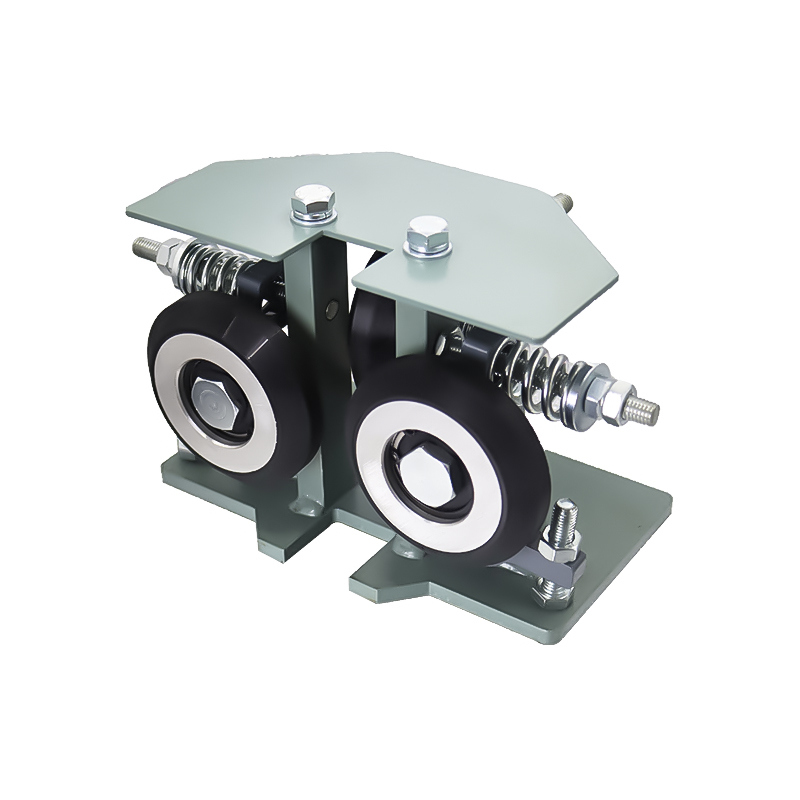

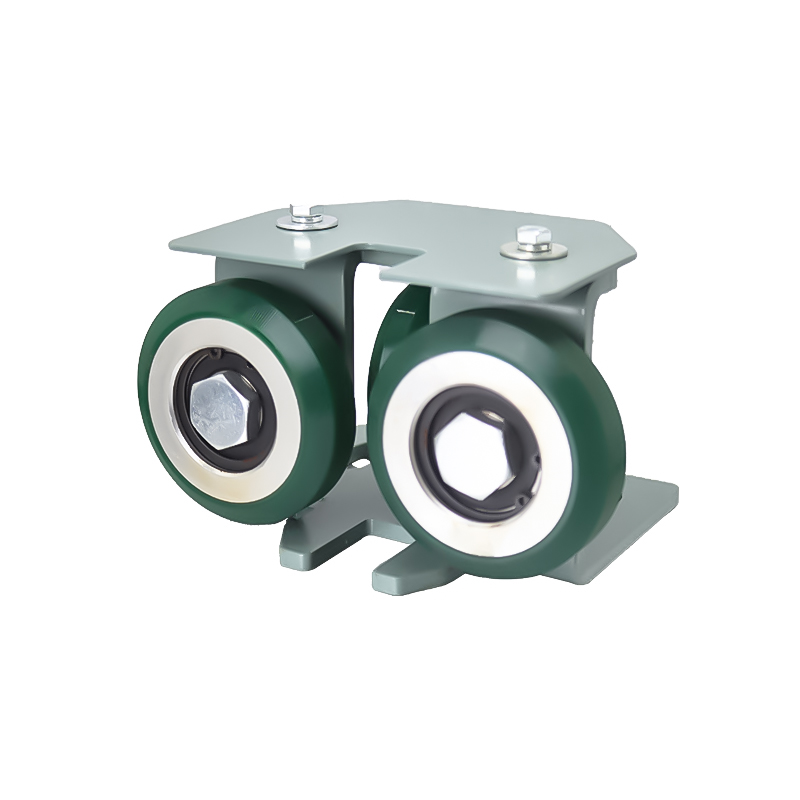

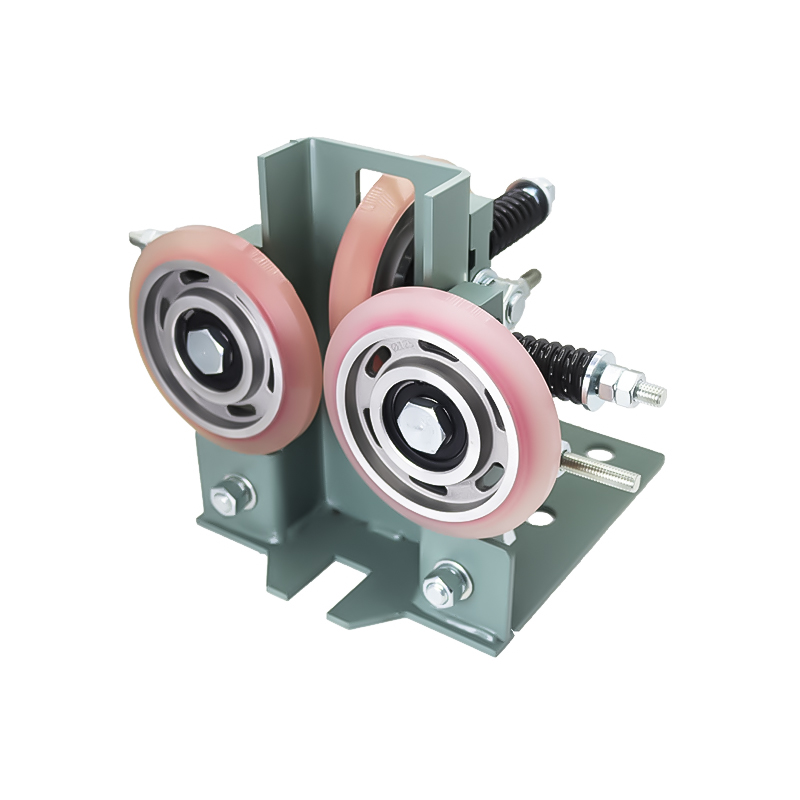

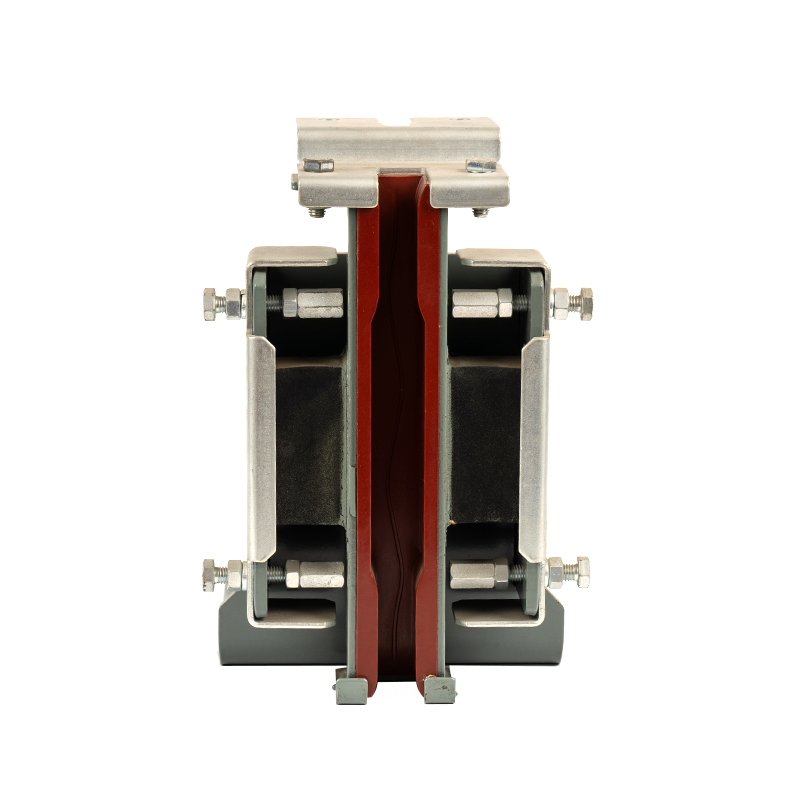

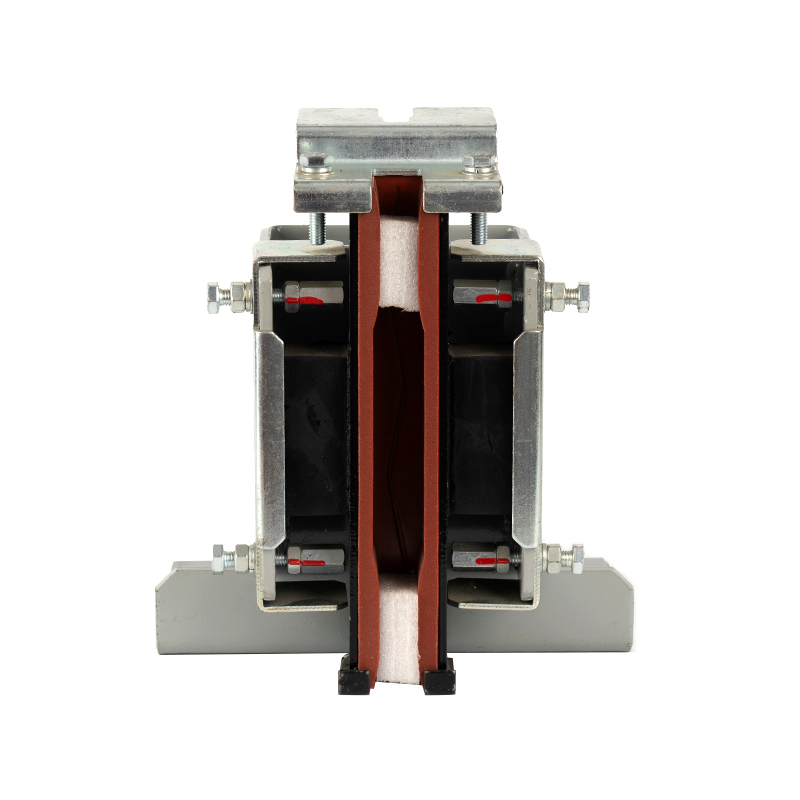

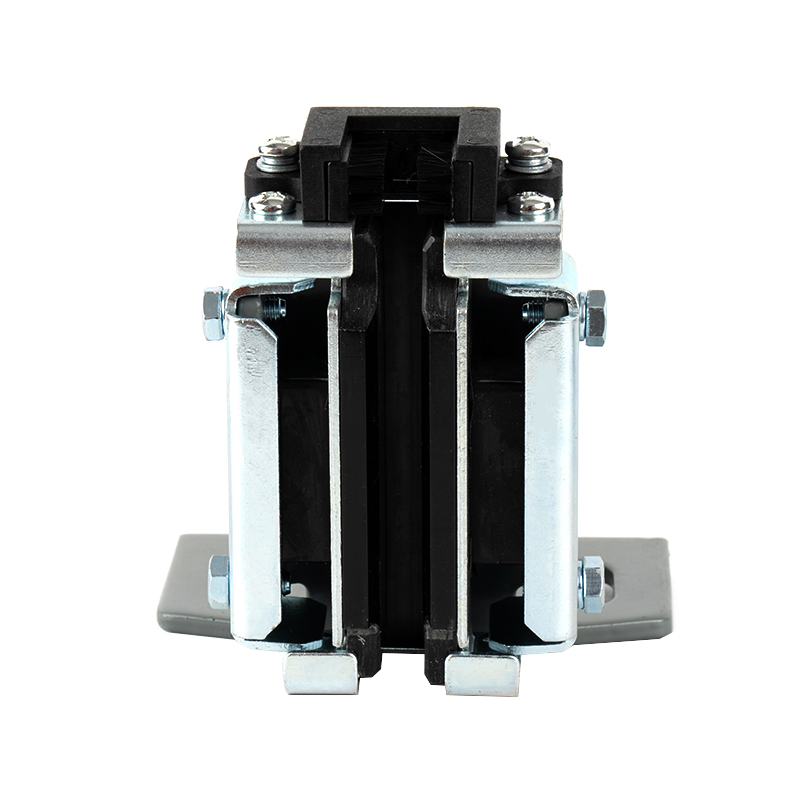

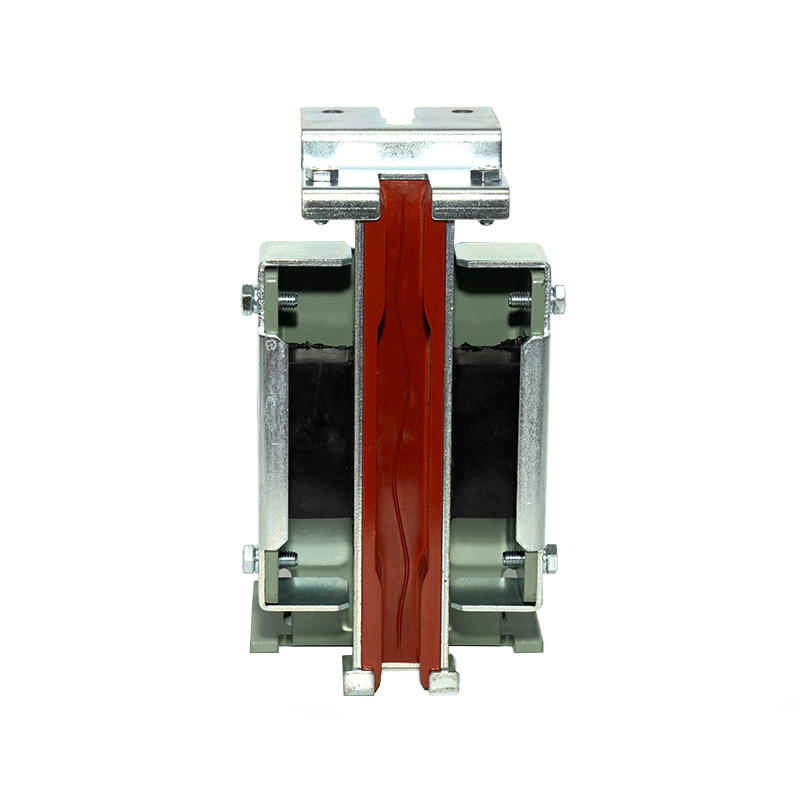

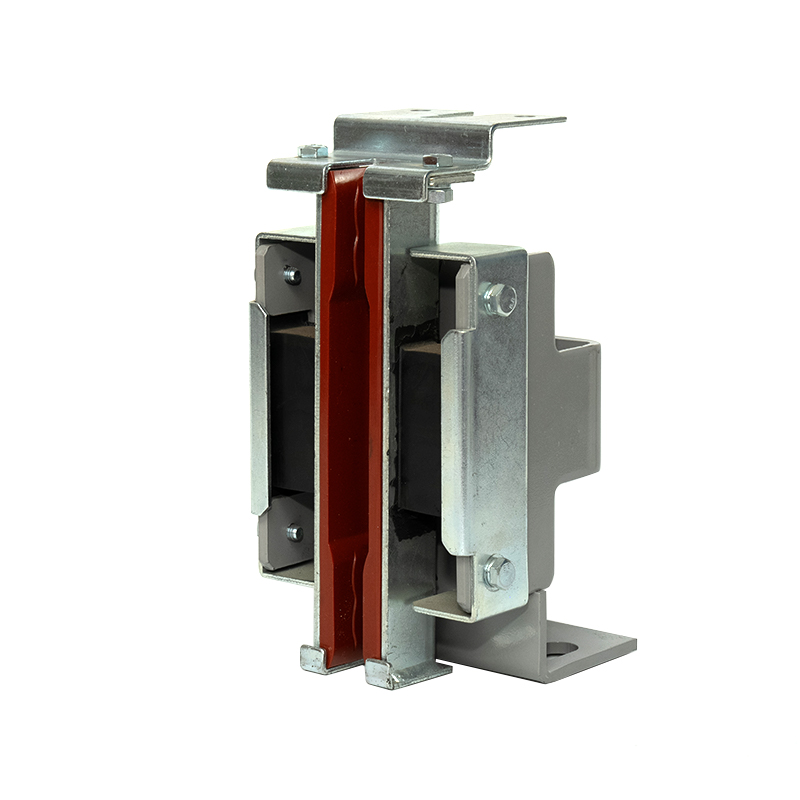

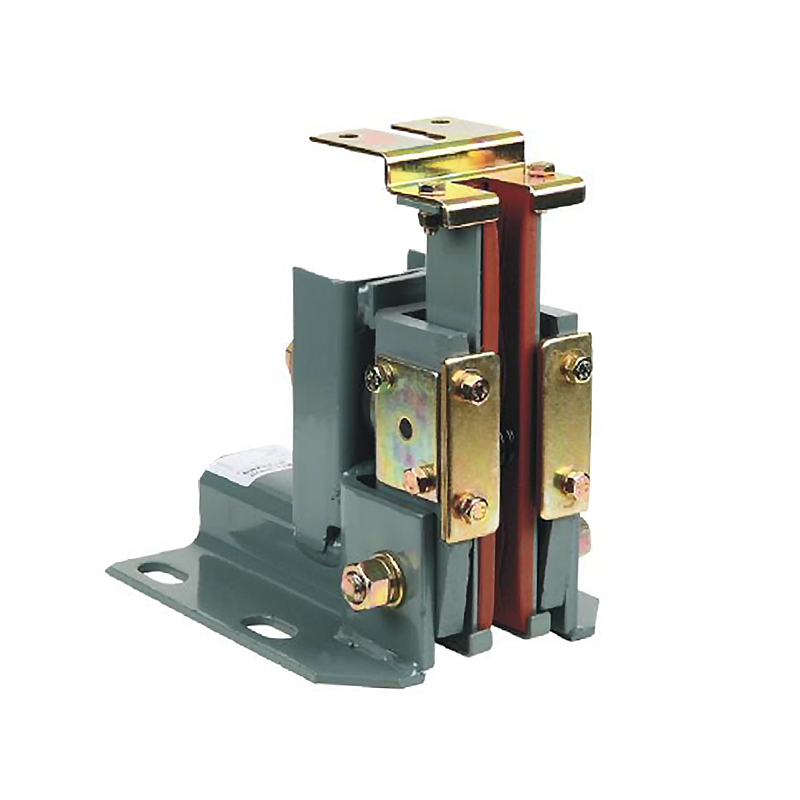

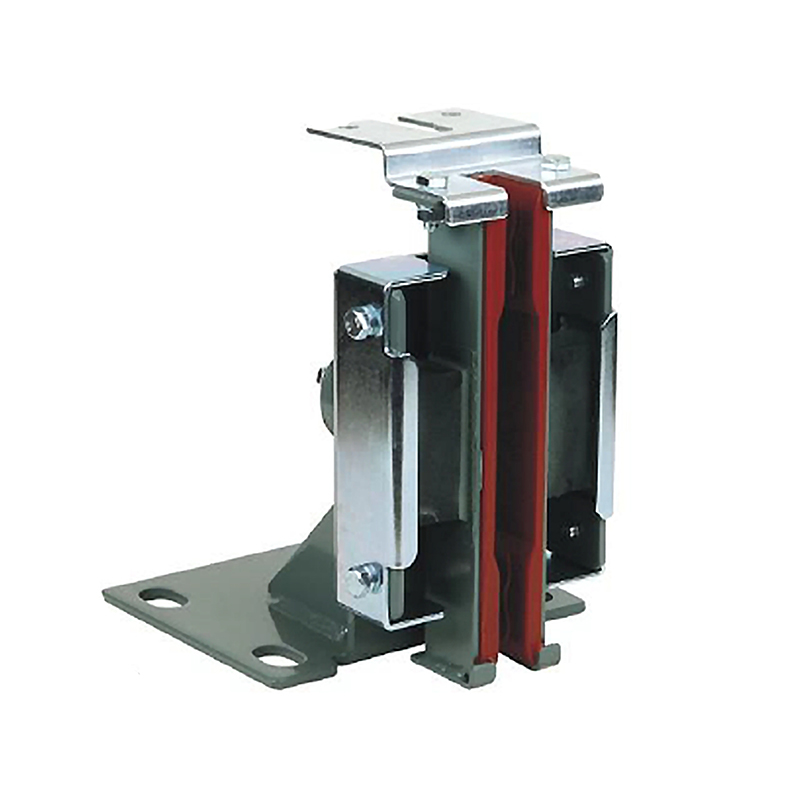

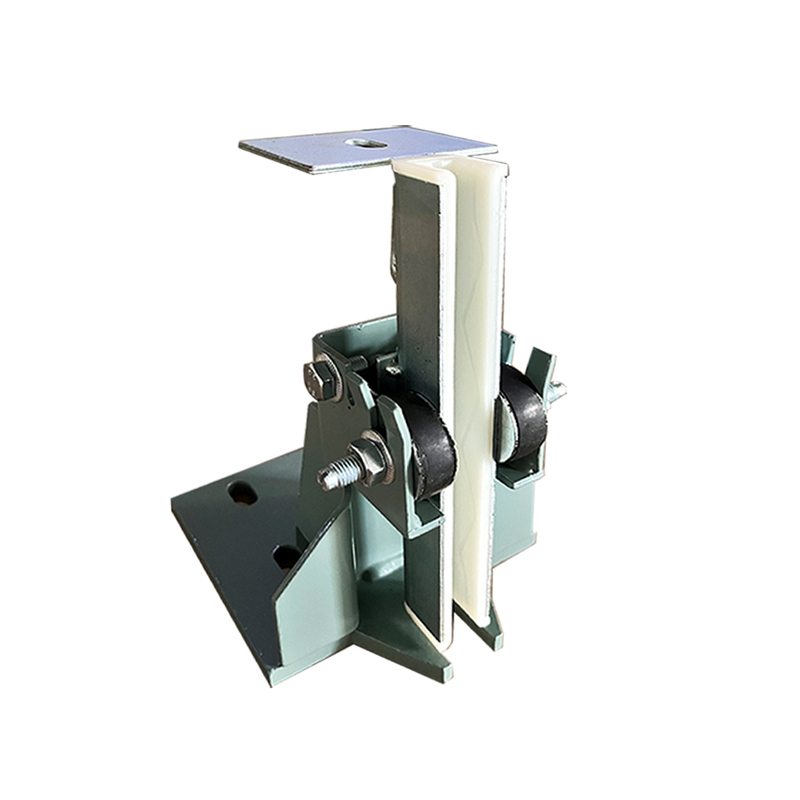

1. Design and materials of roller guide shoes

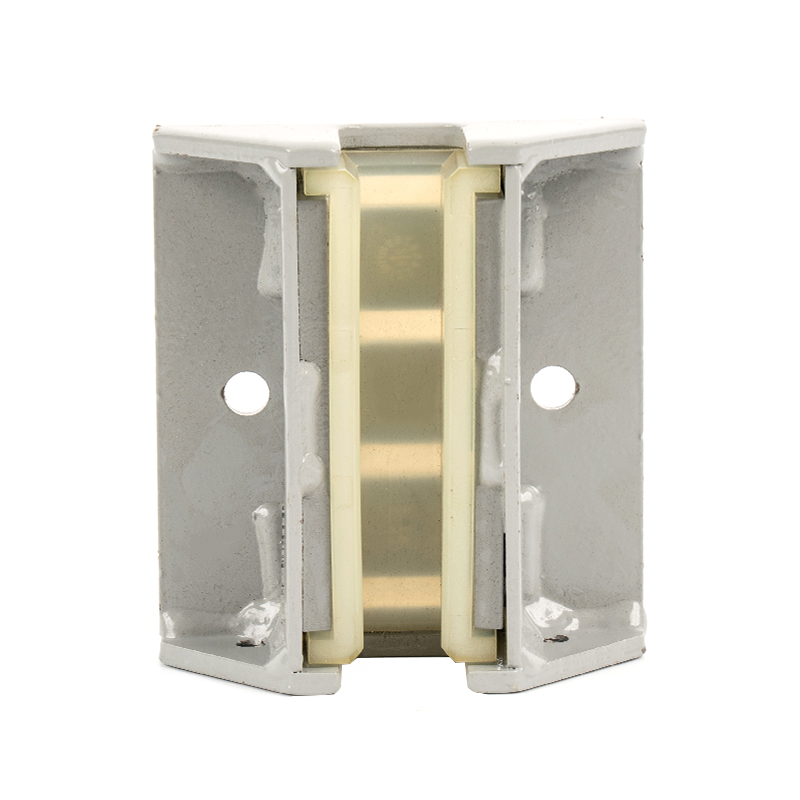

The wear resistance of the Roller Guide Shoe mainly comes from its design and the materials used. Roller guide shoes are usually made of high-strength synthetic materials and engineering plastics, which have good wear resistance and impact resistance and can withstand the high loads generated by the elevator during operation.

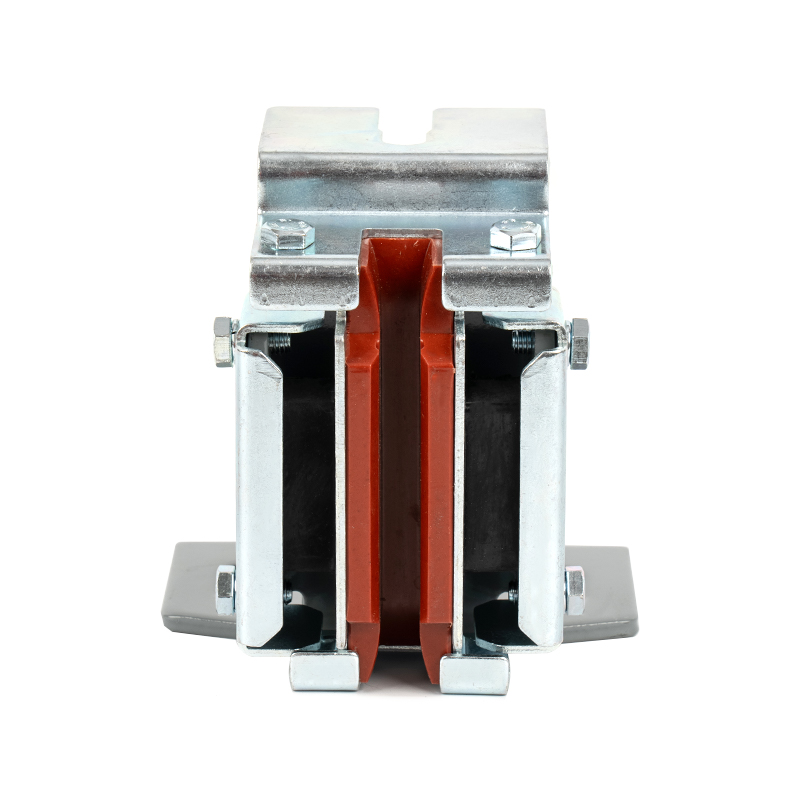

2. Performance under high load

The performance of the Roller Guide Shoe is particularly critical in long-term high-load operation. Its wear resistance ensures that the contact between the roller and the guide rail can maintain a good friction state under high-frequency start-stop and load fluctuations, avoiding wear and failure caused by excessive friction. Specifically:

Stable working state: The roller guide shoe can maintain a stable working state in a long-term high-load environment, reduce elevator failures caused by component wear, and ensure the safety and comfort of passengers.

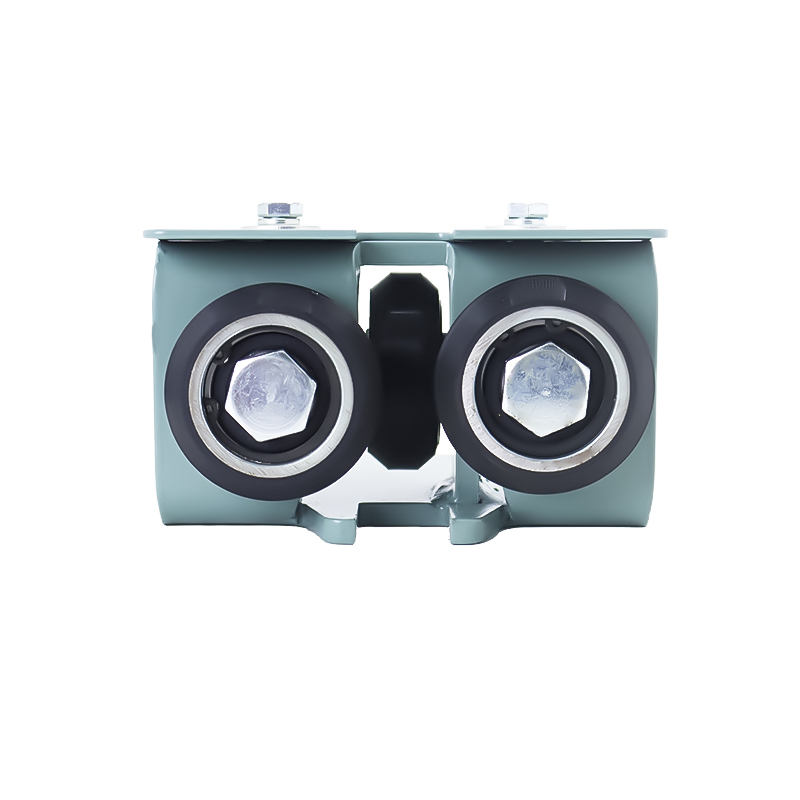

Low wear rate: High-quality roller guide shoes show a low wear rate in long-term high-load operation and maintain good dimensional stability.

3. Impact on the operation efficiency of elevators

The wear resistance of the Roller Guide Shoe not only affects the service life of the elevator, but also has an important impact on its operation efficiency. During high-load operation, if the guide shoe is excessively worn, the noise and vibration of the elevator will increase during operation, and may even cause failures. Good wear resistance can ensure that the elevator can still maintain efficient and stable operation under high-load conditions, and improve the overall service level.

What is the key role of the Roller Guide Shoe in modern elevator systems?

1. Working principle of roller guide shoes

The Roller Guide Shoe achieves rolling contact through its design. Compared with traditional sliding contact, this contact mode greatly reduces the noise and vibration generated by friction. When the elevator is in operation, the rolling contact between the roller and the guide rail can effectively disperse the load and reduce local wear, thereby extending the service life of the components.

2. High stability and wear resistance

The roller guide shoe is known for its high stability and strong wear resistance. These characteristics enable it to perform well in high-frequency, high-load working environments. For buildings such as high-end office buildings, star-rated hotels and high-rise residential buildings, the operating frequency of elevators is often very high, which requires its core components to have extremely high wear resistance to cope with the wear caused by long-term operation.

3. Wide application

The roller guide shoe is widely used in high-speed elevators, including high-end office buildings, star-rated hotels, commercial complexes and super high-rise buildings. With the acceleration of urbanization, the demand for elevators is increasing, and the roller guide shoe has become an ideal choice to meet these needs with its excellent performance. In these application scenarios, elevators not only bear the function of transportation, but also become the embodiment of building quality and image. The high performance of roller guide shoes plays an important role in enhancing the overall building value.

4. Advantages of Ningbo Yinzhou Fukangda Elevator Parts Factory

As an innovative enterprise, Ningbo Yinzhou Fukangda Elevator Parts Factory focuses on the research and development, production and sales of elevator parts. The factory's production center is equipped with advanced hardware and plastic processing equipment, with mature assembly production lines and strict inspection processes. These conditions ensure the high precision, high quality and high performance of roller guide shoes, while also ensuring a stable supply chain. Fukangda has established good cooperative relations with many domestic first-line brands (such as Hitachi, Mitsubishi, Otis, etc.), further enhancing its reputation in the industry.

English

English 中文简体

中文简体