Elevators are an indispensable mode of transportation in modern buildings. Whether in high-rise buildings, shopping malls, or residential areas, the stable operation of elevators directly affects the quality of life for residents and users. As one of the core components of elevator operation, the role of the elevator oil cup is often overlooked. However, it is crucial for the normal operation and long-term use of the elevator. So, why is the elevator oil cup considered a key component in elevator maintenance?

1. Basic Functions of the Elevator Oil Cup

The elevator oil cup is a small component in the elevator system, mainly used to lubricate the elevator's guide rails, wire ropes, hubs, and other mechanical parts. By providing appropriate lubricating oil, it reduces friction between mechanical parts, thereby extending the service life of components and ensuring smooth elevator operation.

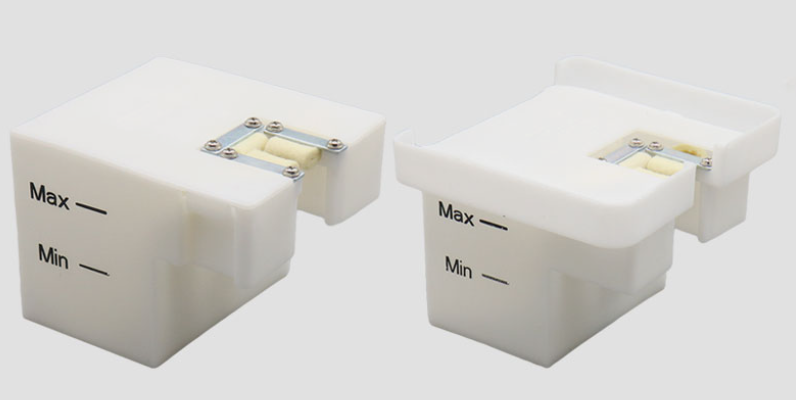

Typically, an elevator oil cup consists of an oil cup body containing oil, oil pipes, and oil nozzles. The oil cup periodically provides lubricating oil to relevant elevator components (such as guide rails and wire ropes). The function of lubricating oil is not only to reduce wear, but also to prevent corrosion of metal parts, reduce noise caused by wear, and improve the efficiency of the elevator.

2. The role of elevator oil cups in elevator operation

(1) Reducing friction and wear

During elevator operation, components such as guide rails, wire ropes, and hubs constantly rub against each other. Without the help of lubricating oil, the friction would increase dramatically, accelerating the wear of these components. Elevator oil cups, by periodically releasing lubricating oil, effectively reduce the friction between these components, allowing the elevator to run smoothly and reducing the wear of mechanical parts. Reducing friction and wear not only extends the service life of the elevator but also improves its operating efficiency.

(2) Reducing noise

During elevator operation, the noise generated by friction often affects the comfort of users. Especially in high-rise buildings and busy commercial environments, elevator noise is more pronounced. The lubricating oil provided by elevator oil cups can effectively reduce mechanical friction, thereby reducing the noise generated by friction. This not only makes the elevator run quieter but also improves the user experience.

(3) Preventing corrosion

Elevator components, especially steel components, are prone to rust and corrosion when exposed to air and moisture for a long time. The lubricating oil provided by the elevator oil cup forms a protective film, effectively isolating moisture in the air from contacting the metal surface and reducing corrosion. This function is crucial, especially in humid environments or harsh weather conditions. The lubricating oil not only protects the surface of the elevator's mechanical components but also prevents safety hazards caused by rust.

(4) Improving Elevator Efficiency and Safety

By regularly lubricating elevator components, the elevator oil cup improves the elevator's operating efficiency, enabling smoother up-and-down movement. Reduced friction lowers the motor load and reduces energy consumption. More importantly, proper lubrication reduces elevator malfunctions caused by uneven wear, preventing unexpected shutdowns due to component damage and ensuring elevator safety.

3. Maintenance and Inspection of Elevator Oil Cups

While the elevator oil cup plays a vital role, its lubrication function will be significantly reduced without proper maintenance, potentially leading to elevator malfunctions. Therefore, regular inspection and maintenance of the elevator oil cup are essential.

(1) Regularly Checking Oil Quantity and Quality

The oil quantity and quality in the elevator oil cup directly affect the lubrication effect. Low oil level or poor oil quality can lead to decreased lubrication and excessive wear of components. During routine elevator maintenance, the oil level and quality in the oil cup should be checked regularly to ensure they meet the elevator's operational needs. If insufficient lubricating oil or deteriorated oil quality is found in the oil cup, it should be replenished or replaced promptly.

(2) Cleaning the Oil Cup and Oil Pipes

During long-term use, impurities such as dust and debris may accumulate in the oil cup and oil pipes, affecting oil flow and lubrication. Therefore, regularly cleaning the elevator oil cup and its oil pipes to keep the oil path unobstructed ensures that lubricating oil is evenly supplied to all components requiring lubrication. If the oil cup is blocked or the oil path is obstructed, lubricating oil cannot be supplied in time, easily leading to unstable elevator operation.

(3) Regularly Checking the Operation of the Oil Nozzles

The oil nozzles are key components for lubricating oil transfer between the oil cup and elevator guide rails and other components. If the oil nozzles are blocked by debris, lubricating oil cannot flow out normally, affecting the lubrication effect. Therefore, regularly checking the working condition of the grease fittings and clearing any blockages to ensure a smooth supply of lubricating oil to all elevator components is an essential task in elevator maintenance.

Although the elevator grease cup is a small component, it plays a crucial role in the normal operation and long-term use of the elevator. Regular lubrication not only reduces friction and wear on mechanical parts, extending their lifespan, but also reduces noise and improves elevator efficiency and safety. To ensure the proper functioning of the elevator grease cup, regular checks of oil level and quality, cleaning of the cup and oil lines, and ensuring unobstructed grease fittings are indispensable maintenance tasks. Only by performing these tasks can the smooth and safe operation of the elevator be guaranteed in daily use.

English

English 中文简体

中文简体