Escalators are indispensable equipment in urban transportation and public buildings, widely used in shopping malls, airports, subway stations, and other places. The smooth operation of escalators directly relates to passenger safety and comfort, and escalator rollers, as one of the key components, are particularly important in their selection and maintenance.

The quality and compatibility of the rollers directly affect the escalator's operating efficiency, noise level, wear and tear, and failure rate. Therefore, understanding how to choose the right escalator rollers is a crucial step in ensuring the normal operation of the escalator.

1. Basic Functions of Escalator Rollers

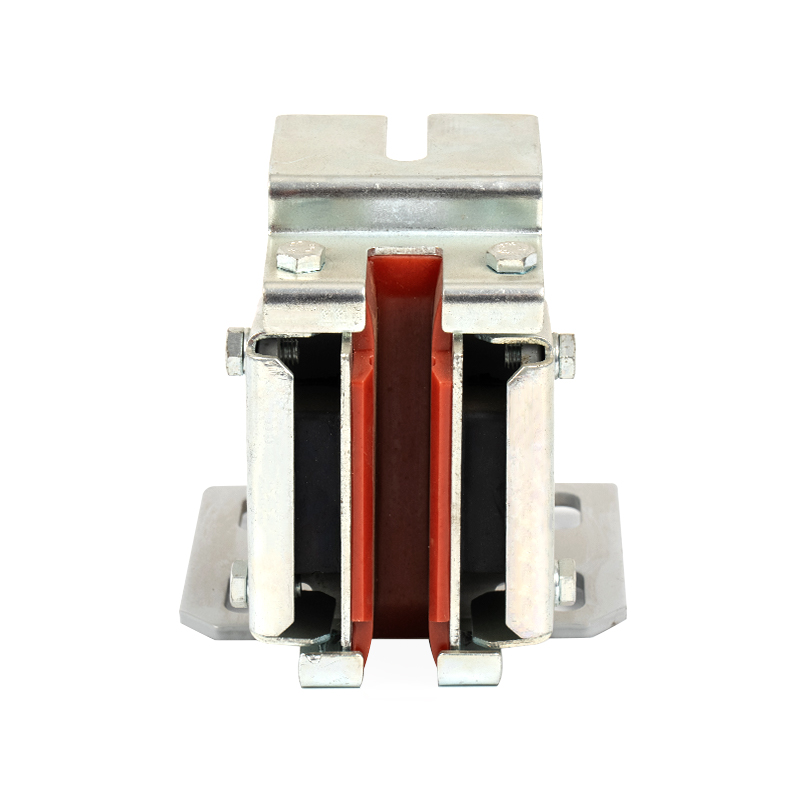

Escalator rollers are located on both sides of the escalator and are primarily used to support the smooth operation of the escalator steps and guide belts. The rollers, through contact with the escalator steps and guide rails, help reduce friction, minimize wear, and provide shock absorption during escalator start-up and stop, maintaining the stability of the system.

Based on different design requirements, escalator rollers are usually divided into several types, including drive rollers, guide rollers, and support rollers, each performing different tasks. Understanding the specific function of each type of roller is crucial for selecting the appropriate rollers.

2. Factors to Consider When Choosing Suitable Escalator Rollers

(1) Material Selection

The material of the rollers directly affects their service life, load capacity, and wear resistance. Common escalator roller materials include:

Rubber: Rubber rollers usually have good shock absorption and wear resistance, effectively reducing noise and extending equipment life. Suitable for medium to low load applications.

Polyurethane: Polyurethane rollers are more wear-resistant than rubber and have stronger oil resistance, making them suitable for frequently used escalators and able to withstand greater pressure and wear.

Steel: Steel rollers have extremely high load capacity and are suitable for escalators that bear heavy loads. Steel rollers usually require the use of lubricating oil to reduce friction.

Plastic or Nylon: Rollers made of these materials are lighter and suitable for escalator systems with special weight requirements. Although their compressive strength and wear resistance are not as good as rubber and polyurethane, they are still ideal choices in some lightweight escalators. Choosing the right materials not only improves escalator operating efficiency but also reduces long-term maintenance costs.

(2) Load Capacity

Different escalator rollers have different load capacities. When selecting rollers, the weight the escalator can bear must be considered. Rollers that are too light may not be able to withstand the escalator load, leading to deformation or damage; while rollers that are too heavy may increase the escalator's operating load, causing unnecessary energy consumption. Therefore, accurately calculating the escalator's maximum load and selecting rollers that meet the specifications is crucial.

(3) Roller Size and Design

The size and design of the rollers directly affect their compatibility with other escalator components. Oversized rollers may not match the escalator guide rails or steps, while undersized rollers may not adequately support the escalator system. The correct roller size and design should ensure more stable and even contact between the rollers, guide rails, and steps during operation, thereby reducing friction and wear and ensuring smooth escalator operation.

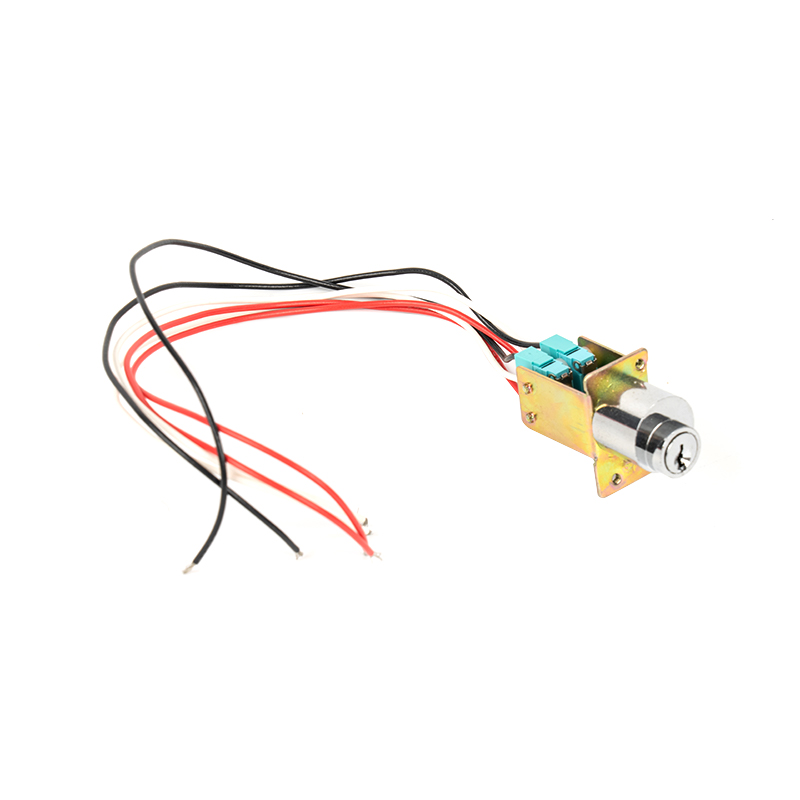

In addition, the roller design should also consider the installation method, adjustability, and compatibility with other components. Different brands and models of escalators may have different installation requirements for rollers, so it is necessary to ensure compatibility between the rollers and the escalator when making a selection.

(4) Wear Resistance and Lifespan

Escalator rollers experience frequent friction during long-term operation. Choosing rollers with good wear resistance can effectively reduce replacement frequency and extend the equipment's service life. Materials such as polyurethane and rubber generally have good wear resistance and corrosion resistance, and can withstand long-term use without easily aging or cracking.

(5) Noise and Vibration Control

In high-frequency use, noise and vibration become a significant problem for escalators. High-quality rollers, through superior material selection and design, can reduce noise and vibration during operation, providing a smoother and more comfortable riding experience. Considering the noise suppression capabilities of the rollers is also an important factor when purchasing.

3. Maintenance and Replacement of Escalator Rollers

In addition to correctly selecting rollers, regular maintenance and timely replacement of rollers are also important aspects of ensuring stable escalator operation. Excessively worn or damaged rollers can not only lead to unstable escalator operation but also affect passenger safety. Therefore, regularly inspecting the wear and tear of escalator rollers and replacing them promptly when problems are found is crucial for ensuring the safe operation of escalators.

During maintenance, in addition to checking the roller surface for cracks or dents, attention should also be paid to the fit between the rollers and the guide rails and whether there are any unusual noises. If excessive wear or abnormal noise is detected in the rollers, the escalator should be stopped immediately for inspection and necessary replacements should be made.

Choosing suitable escalator rollers is not only important for the smooth operation of the equipment but also affects the safety and comfort of passengers. When purchasing rollers, comprehensive consideration should be given to factors such as the escalator's operating environment, load requirements, roller material, and dimensions. Appropriate rollers can improve escalator efficiency, reduce maintenance costs, and extend the equipment's service life. Through proper selection and regular maintenance of rollers, you can ensure that your escalators remain in optimal operating condition, providing safer and more convenient service to passengers.

English

English 中文简体

中文简体