Escalators are essential components in modern buildings, moving large numbers of people efficiently between floors. One of the key parts that ensures smooth operation is the escalator roller. In this article, we will explore what escalator rollers are, how they function, and why they are so important for escalator performance and maintenance.

Content

What Are Escalator Rollers?

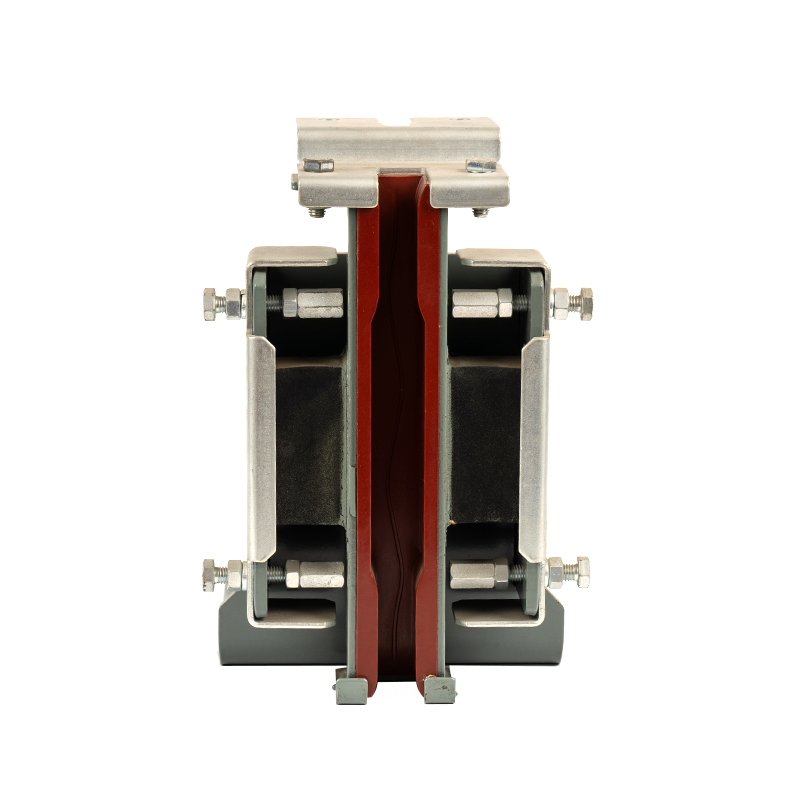

Escalator rollers are mechanical components used to support the escalator steps and ensure smooth movement along the tracks. These rollers are positioned on the underside of the steps and help guide them along the escalator’s track system. Escalator rollers are made of durable materials like steel or high-performance polymers, designed to handle constant friction and heavy loads without wearing down quickly.

How Do Escalator Rollers Work?

The primary function of escalator rollers is to facilitate the movement of the escalator steps as they travel along the escalator’s incline. They provide a smooth and controlled path for the steps, reducing friction between the moving parts. Escalator rollers are typically installed on the step chain, helping each step rotate smoothly along its guide rails.

Components of an Escalator Roller System

- Roller Bearings: These allow the rollers to rotate smoothly, minimizing friction.

- Housing: The housing encases the roller bearings, providing stability and protection from dust and debris.

- Track Guides: Track guides help the rollers align with the escalator track, ensuring smooth step movement.

Why Are Escalator Rollers Important?

Escalator rollers play a crucial role in ensuring the safety, efficiency, and longevity of an escalator system. Below are a few reasons why these components are so important:

1. Smooth Operation

Escalator rollers are vital for minimizing friction and ensuring the smooth operation of escalators. Without high-quality rollers, the escalator steps could experience resistance, leading to a jerky motion and potential mechanical issues.

2. Safety

Since escalators are designed to transport people, maintaining smooth step movement is essential for safety. Any malfunction or wear in the rollers can cause misalignment, increasing the risk of accidents.

3. Reduced Maintenance Costs

Escalator rollers help extend the life of the escalator by reducing the wear and tear on the steps and track system. By ensuring the proper function of the escalator, the need for frequent repairs or replacements is minimized, resulting in lower maintenance costs.

How to Maintain Escalator Rollers?

Regular maintenance of escalator rollers is essential to ensure optimal performance and prevent issues. Some key maintenance tips include:

1. Lubrication

Ensure that the roller bearings are regularly lubricated to reduce friction and wear. Proper lubrication can significantly extend the lifespan of the rollers.

2. Inspection

Regularly inspect the rollers for any signs of wear, such as cracks, deformation, or excessive noise during operation. Timely replacement of damaged rollers can prevent larger issues with the escalator.

3. Cleaning

Keep the rollers clean and free from dust, dirt, and debris. Accumulation of particles can affect the roller’s performance, causing increased friction and potential damage.

Escalator rollers are critical components that ensure the efficient and safe operation of escalators. By reducing friction, facilitating smooth step movement, and extending the lifespan of the escalator, they play a vital role in the overall functionality of escalators. Regular maintenance and timely replacement of worn rollers are essential for keeping escalators running smoothly and safely, making them a key part of the escalator system.

English

English 中文简体

中文简体