The elevator oil cup is a small but critical component in elevator maintenance systems. It ensures smooth lubrication of moving parts, reduces friction, and helps extend the service life of elevator guide rails and mechanical assemblies. Understanding how an elevator oil cup works can significantly improve elevator safety and long-term performance.

Content

What Is an Elevator Oil Cup?

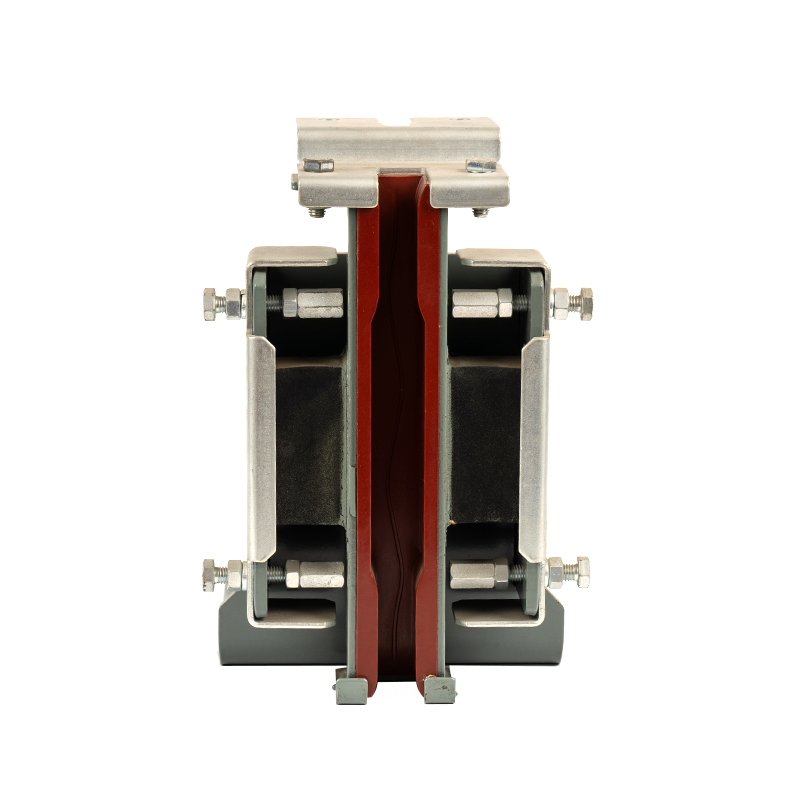

Short Answer: An elevator oil cup is a lubrication device used to deliver controlled amounts of oil to elevator guide rails and moving components.

Installed near guide shoes or rail lubrication points, the elevator oil cup releases oil gradually to maintain consistent lubrication. This prevents metal-to-metal contact and reduces wear on elevator parts. Because elevators operate continuously in high-rise buildings, reliable lubrication is essential for stable and quiet operation.

Why Is an Elevator Oil Cup Important for Elevator Systems?

Short Answer: It improves operational efficiency, reduces maintenance costs, and enhances passenger comfort.

Without proper lubrication, friction increases and components wear out faster. The elevator oil cup ensures a steady oil supply, minimizing vibration and noise. It also protects guide rails from corrosion and surface damage, helping elevators operate smoothly over long periods.

- Reduces friction and mechanical wear

- Improves ride comfort and stability

- Extends the service life of elevator components

- Lowers long-term maintenance expenses

How Does an Elevator Oil Cup Work?

Short Answer: It delivers oil gradually through gravity or capillary action to maintain consistent lubrication.

The elevator oil cup stores lubricant and releases it in controlled amounts. As the elevator operates, guide shoes or rollers pass through lubricated areas, spreading oil evenly along the rail surface. This method ensures that lubrication remains stable even during frequent elevator usage.

Below is a simple comparison of common elevator oil cup types and their applications:

| Oil Cup Type | Lubrication Method | Typical Application |

| Gravity Type | Natural oil flow | Standard elevators |

| Wick Type | Capillary absorption | High-precision systems |

How to Maintain an Elevator Oil Cup Properly?

Short Answer: Regular inspection and timely refilling ensure stable lubrication performance.

Routine maintenance includes checking oil levels, cleaning the oil cup to prevent contamination, and ensuring the outlet is not blocked. Using the correct lubricant type also helps prevent residue buildup and guarantees smooth oil flow. Scheduled maintenance improves overall elevator reliability.

- Inspect oil levels regularly

- Clean the oil cup and outlets

- Use suitable lubrication oil

- Replace damaged components promptly

FAQ: Elevator Oil Cup Common Questions

Q1: How often should an elevator oil cup be refilled?

Answer: It depends on elevator usage frequency, but most systems require inspection and refilling every one to three months.

Answer: It depends on elevator usage frequency, but most systems require inspection and refilling every one to three months.

Q2: Can an elevator operate without an oil cup?

Answer: While possible for short periods, operating without proper lubrication increases wear and may cause long-term damage.

Answer: While possible for short periods, operating without proper lubrication increases wear and may cause long-term damage.

Q3: What problems indicate oil cup malfunction?

Answer: Increased noise, vibration, or uneven elevator movement often indicate lubrication issues.

Answer: Increased noise, vibration, or uneven elevator movement often indicate lubrication issues.

Q4: Are elevator oil cups suitable for all elevator types?

Answer: Yes, most traction and hydraulic elevator systems use oil cups for guide rail lubrication.

Answer: Yes, most traction and hydraulic elevator systems use oil cups for guide rail lubrication.

By understanding the function and maintenance of an elevator oil cup, building managers and technicians can improve elevator performance, enhance safety, and reduce operational costs. This small component plays a big role in reliable elevator operation.

English

English 中文简体

中文简体