The safety and comfort of an elevator directly affect passenger experience and building operational efficiency. Elevator sliding guide shoes are crucial components in an elevator system; their quality and compatibility directly impact the elevator's smooth operation and safety. Therefore, choosing the right elevator sliding guide shoes is key to ensuring long-term stable elevator operation.

1. What are Elevator Sliding Guide Shoes?

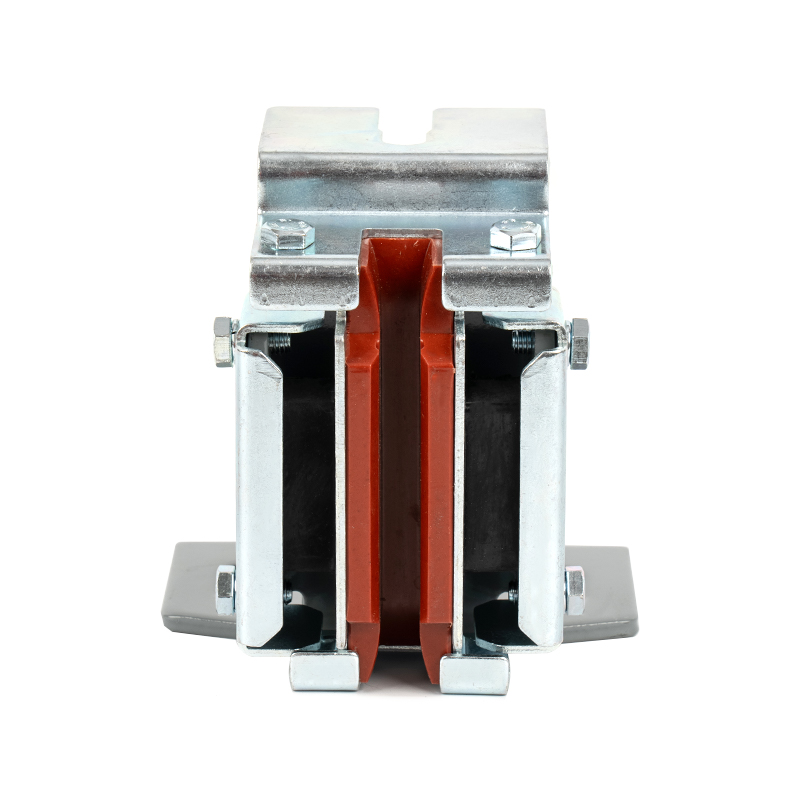

Elevator sliding guide shoes (also called elevator guide shoes or slippers) are a set of components installed on the elevator car guide rails. Their main function is to ensure the car slides smoothly along the guide rails. Through friction with the guide rails, the guide shoes help reduce elevator car vibration and noise, ensuring smooth and efficient elevator operation. In addition, the guide shoes also provide guidance and shock absorption, preventing unnecessary shaking or instability of the elevator car during operation.

2. How to Choose the Right Elevator Sliding Guide Shoes?

Choosing the right elevator guide shoe requires considering several factors, including material, structure, working environment, and maintenance requirements. Below, we will detail several key factors to consider when selecting elevator guide shoes:

(1) Material Selection

The material of the elevator guide shoe directly affects its durability, friction performance, and operating temperature range. Common guide shoe materials include:

Polyurethane (PU): Polyurethane is a commonly used guide shoe material with good wear resistance, impact resistance, and shock absorption. It reduces noise during use and effectively extends the service life of the elevator guide rail.

Nylon: Nylon guide shoes are wear-resistant, corrosion-resistant, and have good self-lubricating properties. Under most normal operating conditions, nylon guide shoes provide a smooth sliding effect.

Steel Alloy: Suitable for elevators that need to withstand large loads or high-intensity operating environments. Steel alloy guide shoes have high strength and are suitable for high-speed or heavy-duty elevators.

Composite Materials: Composite material guide shoes combine the advantages of multiple materials, possessing higher wear resistance and durability, and are suitable for complex working environments. When selecting appropriate materials, it is essential to consider the elevator type, load, and operating environment. For elevators with frequent use and heavy loads, it is recommended to choose more robust and durable materials.

(2) Load Capacity and Adaptability

Different elevator designs have different load requirements. When selecting guide shoes, it is essential to ensure they can withstand the loads during elevator operation. Insufficiently small guide shoes may not provide enough support, leading to elevator instability or even malfunction; while excessively large guide shoes may increase unnecessary friction, resulting in decreased energy efficiency and accelerated component wear.

When selecting elevator guide shoes, appropriate specifications should be chosen based on the elevator's rated load, car size, and operating speed. Furthermore, the compatibility between the guide shoe and the guide rail must be considered to ensure seamless and error-free installation for smooth operation.

(3) Working Environment

The working environment of the elevator has a significant impact on the selection of guide shoes. Elevators may operate in different environments, such as:

Temperature: If the ambient temperature of the elevator is low or high, it is important to select guide shoe materials that can withstand extreme temperatures. Some materials are prone to becoming brittle at low temperatures, while high temperatures may cause material deformation or performance degradation.

Humidity and Corrosion: If the elevator operates in a humid environment or where there are chemical corrosive substances (such as in industrial plants), it is necessary to select guide shoe materials with strong corrosion resistance, such as acid and alkali resistant and moisture-resistant composite materials.

Noise Requirements: In some places with high noise requirements (such as residential or office buildings), low-noise guide shoes need to be selected. Polyurethane materials have good vibration damping effects and can effectively reduce the noise during elevator operation.

3. Maintenance and Care

The maintenance and care of elevator guide shoes are related to their service life and the overall performance of the elevator. Selecting guide shoes that are easy to clean and maintain can reduce the workload of daily maintenance and lower operating costs. For example, some elevator guide shoes have a self-lubricating function, reducing the need for frequent lubrication and helping to improve operating efficiency.

Furthermore, considering the wear of elevator guide shoes, it is also important to choose guide shoes that are easy to replace or adjust. Regularly check the wear of the guide shoes to ensure they are not excessively worn or damaged, guaranteeing the safe operation of the elevator.

When selecting suitable elevator guide shoes, material, load capacity, working environment, and maintenance requirements should be considered. By understanding these key factors, you can select the most suitable guide shoes for your elevator, ensuring safe and efficient operation and extending its service life. Timely maintenance and regular inspections are also crucial for ensuring stable elevator operation; therefore, a comprehensive evaluation should be conducted based on actual conditions when purchasing guide shoes.