The following are five key warning signs of elevator guide shoe wear. Combining professional maintenance experience and real-world cases, we'll help you promptly identify potential faults and take corrective measures:

Content

1.Abnormal Operational Noise (Rubbing, Scratching)

Symptoms: A continuous "squeaking," "clicking," or sharp metallic rubbing noise is heard when the elevator is moving up or down, especially during starting or braking.

Cause: Worn guide shoe pads are in direct contact with the guide rails, or loose guide shoe fixing screws are causing metal-to-metal collisions.

Risk: Long-term neglect may accelerate guide rail wear and even lead to the risk of car derailment.

2. Increased Car Vibration or Horizontal Sway

Symptoms: Passengers noticeably feel the elevator's unstable movement, especially under heavy loads.

Cause: Worn guide shoes lead to uneven clearance with the guide rails, or guide shoe spring failure is failing to buffer vibrations.

Check: Use a spirit level to measure the car tilt. If the tilt exceeds 2mm, immediate inspection is required.

3. Increased Leveling Error (Inaccurate Stopping)

Symptoms: A significant height difference between the elevator and the floor (e.g., exceeding ±5mm) occurs when the elevator stops.

Cause: Guide shoe wear reduces guiding accuracy, causing the elevator car to deviate from its trajectory.

Impact: This may cause passengers to trip and exacerbate door system malfunctions.

4. Visible Wear or Deformation of the Guide Shoe Liner

Symptoms: Inspection of the guide shoe liner (usually made of nylon or polyurethane) reveals uneven thickness, cracks, or missing parts.

Standard: Replacement is required if the remaining thickness is less than 50% of the original design or if partial peeling occurs.

Tool: Use a caliper to measure and compare to the manufacturer's wear limit.

5. Abnormally Increased Energy Consumption

Symptoms: Increased elevator motor current or power consumption, especially at low speeds.

Cause: Increased guide shoe friction coefficient due to wear requires the traction system to perform additional work.

Data: Measurements show that severely worn guide shoes can increase energy consumption by 10%-15%.

Recommendations

Regular Inspection: Measure the guide shoe clearance and liner thickness every three months, and use a laser alignment tool to adjust the guide shoe position.

Lubrication and Maintenance: Use lithium-based grease to avoid dry friction (rolling guide shoes do not require lubrication).

Timely Replacement: Composite liners (such as ultra-high molecular weight polyethylene) are preferred, as they offer a 30% longer lifespan than traditional nylon.

If any of the above signs are observed, contact professional maintenance personnel immediately to avoid a cascading failure.

Elevator Guide Shoe FAQs

- What is an elevator guide shoe? What is its function?

Definition: A guide shoe is a guide component installed on the elevator car and counterweight, ensuring smooth elevator operation along the guide rails.

Function:

Maintains vertical car movement and prevents side-to-side sway or yaw.

Reduces vibration and noise, improving ride comfort.

Some guide shoes have lubrication functions to reduce guide rail wear.

- What types of guide shoes are there? How to choose?

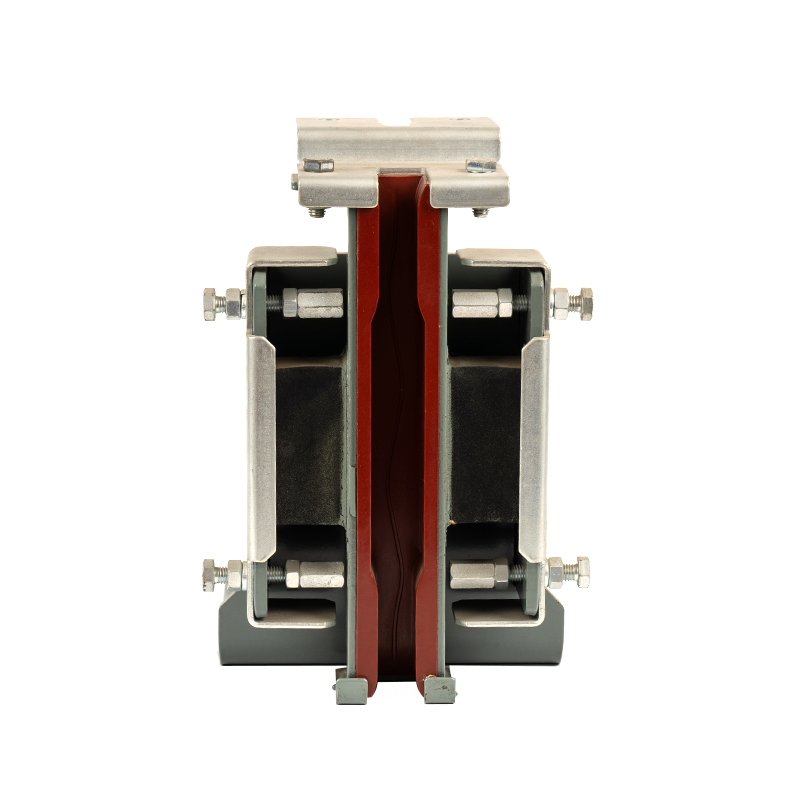

Sliding guide shoes (traditional):

Simple structure, low cost, suitable for low-speed elevators (≤1.0 m/s).

Requires regular lubrication and wears faster.

Roller guide shoes (modern):

Uses rollers instead of sliding friction, suitable for medium- and high-speed elevators (≥1.5 m/s).

No lubrication required, long life, but higher price.

Suggested selection: Determine based on elevator speed, load, and operating environment (such as humidity and high temperatures).

- Do guide shoes require lubrication? How should they be lubricated correctly?

Sliding guide shoes require lubrication:

Use lithium-based grease or a dedicated guide shoe lubricant.

Lubricate every 3-6 months to avoid excessive oil accumulation.

Roller guide shoes do not require lubrication:

The rollers have sealed bearings, so lubrication may attract dust.

- Does guide shoe wear affect elevator safety?

Potential risks:

Increased guide rail wear can lead to unstable operation.

In severe cases, it may cause the car to derail or make an emergency stop.

Solution: Regularly inspect and replace worn parts promptly.

English

English 中文简体

中文简体