Content

1. Common types of roller failure

Mechanical failure

Bearing stuck: Insufficient lubrication or foreign matter intrusion causes damage to the rolling element and the roller cannot rotate.

Rim wear: Long-term friction causes the rim to become thinner or cracked, and loses its guiding function.

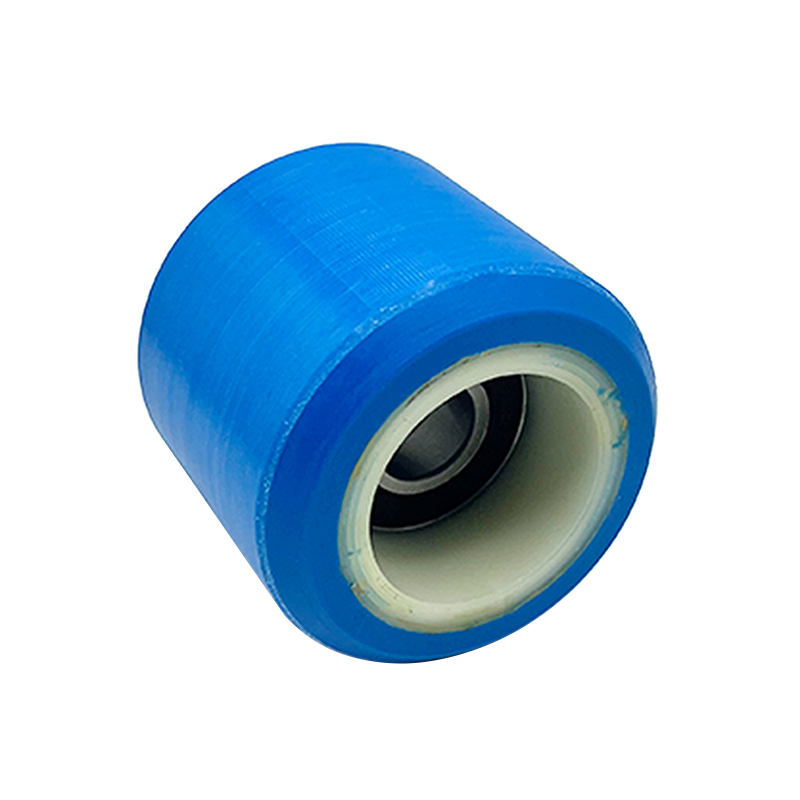

Aging of rubber/polyurethane: Surface cracking and hardening, and reduced shock absorption performance.

Functional failure

Eccentric operation: Wear of the bushing causes the roller to shake, causing the step to deviate.

Abnormal noise: Damage to the bearing or deformation of the wheel body produces a harsh friction sound.

2. Safety hazards caused by roller failure

Step derailment or sudden stop

Risk scenario:

When the guide wheel fails, the step may derail, causing passengers to fall.

The drive wheel slips or gets stuck, and the escalator stops suddenly, causing passengers to fall by inertia.

Step jitter and abnormal gap

Risk manifestation:

Worn rollers make the steps run unsteadily and produce obvious vibrations.

The gap between the steps increases (>4mm), which may pinch shoes or children's fingers.

Standard requirements:

GB 16899-2011 stipulates that the step gap must be ≤4mm and the vertical jitter must be ≤0.5mm.

Fire risk (rare but serious)

Causes:

The dry friction between the metal roller and the guide rail produces high-temperature sparks, which ignites grease or dust.

Polyurethane wheels overheat and carbonize, releasing toxic fumes.

3. How to identify signs of roller failure?

Daily inspection points

|

Symptoms |

Possible failure components |

Emergency treatment measures |

|

Abnormal noise (metal friction sound) |

Bearing damage/wheel deformation |

Stop for inspection, replace bearings or rollers |

|

Steps swaying left and right |

Guide wheel wear or eccentricity |

Adjust wheel width or replace wheel set |

|

Escalator running jams |

Drive wheel slipping or insufficient lubrication |

Clean the track and add grease |

Professional testing tools

Vibration analyzer: detects the degree of bearing wear (replacement is required when the vibration value is greater than 7.1mm/s).

Infrared temperature gun: there is a risk of overheating when the wheel body temperature is greater than 70℃.

4. Escalator roller maintenance tips: Extend life and ensure safety

Daily inspection and cleaning

Inspection frequency

Daily (applicable to high-frequency use places, such as subways and shopping malls):

Observe whether the roller rotates flexibly and whether there is any abnormal noise.

Check whether the steps run smoothly and whether there is obvious shaking.

Weekly (applicable to ordinary commercial escalators):

Check whether there are cracks, deformation or abnormal wear on the roller surface.

Clean the dust and oil around the guide rails and rollers to prevent impurities from accelerating wear.

Key inspection areas

|

Roller type |

Inspection content |

Abnormal performance |

|

Step wheel |

Rim thickness, bearing rotation |

Rim wear > 20%, rotation jam |

|

Guide wheel |

Contact surface between wheel body and guide rail |

Surface peeling, eccentric shaking |

|

Drive wheel |

Tooth surface wear, lubrication status |

Tooth deformation, grease drying |

Lubrication management (key!)

Lubricant selection

Bearing lubrication: high viscosity lithium-based grease (temperature range -30℃~120℃).

Guide lubrication: synthetic lubricant (low dust absorption, such as ISO VG 68).

Lubrication cycle and method

|

Lubrication parts |

Frequency |

Operation method |

|

Roller bearings |

Every 3 months |

Remove the roller, clean the old grease and add new grease (the amount of grease added accounts for 60% of the bearing cavity) |

|

Guide contact surface |

Every month |

Use a brush or automatic lubrication system to apply evenly |

|

Drive sprocket |

Every 6 months |

Remove the old grease and apply high temperature resistant grease |

Common mistakes

Over-lubrication: causes grease to splash and absorb dust to form abrasives.

Mixed greases: Different brands of grease may react chemically, reducing the lubrication effect.

Preventive maintenance upgrade suggestions

Use maintenance-free rollers

Self-lubricating nylon wheels: suitable for low-load scenarios (such as shopping malls), with a lifespan of 8-10 years.

Ceramic coated bearings: high temperature resistant, corrosion resistant, suitable for high-frequency use environments such as subways.

Install an intelligent monitoring system

Vibration sensor: real-time monitoring of bearing status, early warning of failures.

Temperature alarm: automatic shutdown when the roller temperature is >70°C.

English

English 中文简体

中文简体