Content

1. Four Core Technologies of Roller Guide Shoes

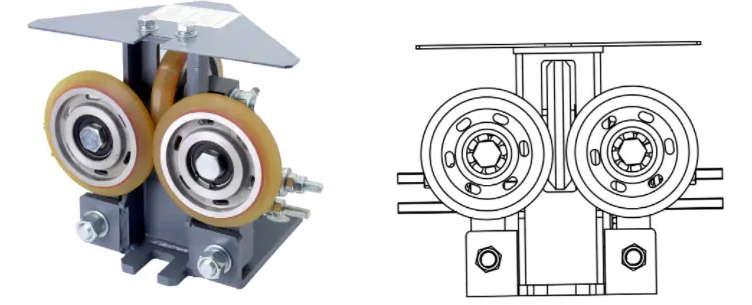

Precision Bearing Design: Reduces Rolling Resistance

Double-Row Angular Contact Ball Bearings: Withstands Radial and Axial Loads, Ensuring High-Speed Roller Rotation without Binding

Preload Adjustment: A spring or hydraulic mechanism maintains constant contact between the roller and the guide rail, preventing bouncing.

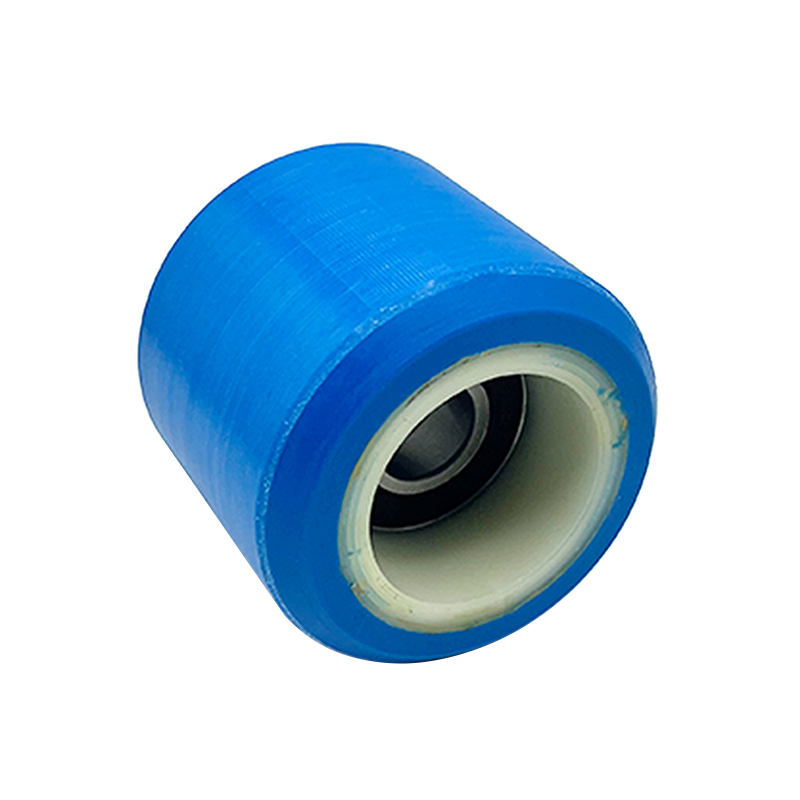

Polymer Material Rollers: Balances Shock Absorption and Wear Resistance

Polyurethane (PU) Rollers: Highly elastic and wear-resistant, absorbing micro-vibrations caused by guide rail unevenness.

Nylon Composite Rollers: Suitable for high-speed elevators (>2.5 m/s), with strong deformation resistance.

Dynamic Self-Aligning Structure: Accommodates Guide Rail Deflection

Floating Mounting: Allows the roller to adapt to guide rail installation errors within a ±3° range.

Elastic Support System: Rubber pads or springs cushion transient impact forces (such as during an emergency stop).

Lubrication Technology Innovation: Maintenance-Free and Long-Life

Self-lubricating bearings: Built with graphite or PTFE, no external lubrication is required.

Sealed design: Dust- and water-resistant, preventing impurities from entering the rollers and affecting performance.

2. Common Elevator Roller Guide Shoe Problems and Solutions (Maintenance Guide)

Abnormal Roller Wear

- Uneven Roller Surface Wear

Possible Causes:

Guide Rail Installation Deviation (Horizontal/Vertical Tolerance Exceeded)

Car Unbalanced Loading Leading to Excessive Force on One Side

Unqualified Roller Material (Insufficient Hardness or Deterioration)

Solution:

Check Guide Rail Straightness: Use a laser alignment tool to ensure deviation is less than 0.5 mm/m.

Adjust Car Balance: Check the counterweight configuration to ensure even load distribution.

Replace High-Wear Rollers: Choose polyurethane (PU) or nylon composite materials (recommended Shore hardness 75A-85A).

- Premature roller cracking or deformation

Possible causes:

Overload (exceeding 150% of the rated load)

Excessively high ambient temperature (>60°C) causing softening of the PU roller

Chemical corrosion (such as strong acids or alkalis in cleaning agents)

Solution:

Install an overload protection device: Link the elevator control system to limit overload operation.

Replace high-temperature rollers: Choose nylon or PTFE composite materials (suitable for -30°C to 120°C).

Avoid chemical contact: Use a neutral solvent (such as alcohol) when cleaning.

Abnormal Operational Noise

- A "creaking" sound during rolling

Possible causes:

Lack of bearing oil or dust intrusion

Worn roller pin causing increased clearance

Hard particles (such as sand and gravel) on the guide rail surface

Solution:

Clean and lubricate the bearings: Use high-temperature grease (such as lithium-based grease). Sealed bearings should be replaced immediately.

Replacing the pin: Check the pin diameter for wear (>0.2mm requires replacement). Clean the guide rails: Use fine sandpaper to polish the guide rail contact surface to remove impurities.

- High-frequency "buzzing" vibration

Possible causes:

Failure of roller dynamic balancing (e.g., internal bearing damage)

Resonance between the elevator's operating speed and the roller's natural frequency

Solution:

Replace the roller assembly: Prefer genuine parts (dynamic balancing accuracy ≤ 0.5g·cm).

Adjust the elevator's operating curve: Use the inverter to reduce acceleration and avoid the resonant frequency band.

Guide shoe jamming

- Sluggish roller rotation

Possible causes:

Bearing corrosion (caused by a humid environment)

Insufficient clearance between the roller and the guide rail (improper installation)

Solution:

Replace stainless steel bearings: Suitable for high-humidity environments (e.g., elevators in underground garages).

Adjust the guide shoe clearance: Use a feeler gauge to measure; a clearance of 0.5-1mm per side is recommended (refer to manufacturer's standards).

Other Systemic Failures

- The guide shoe is completely deflected or loose.

Possible Causes:

Loose mounting bolts (due to vibration)

Deformed guide shoe bracket (due to external impact)

Solution:

Tighten the bolts and apply anti-loosening seal: Use a torque wrench (tighten to the manufacturer's specified torque).

Align or replace the bracket: Use a level to check the bracket flatness (error <1mm/m).

3. Frequently Asked Questions (FAQ) about Elevator Roller Guide Shoes

- How do I determine if a roller needs replacement?

Replacement criteria:

Wear: Roller diameter reduction > 2mm (measured with a caliper).

Surface cracks: Visible cracking or peeling.

Abnormal noise/vibration: Noticeable creaking or shaking during operation.

- Do roller guide shoes require lubrication?

Most do not:

Modern roller guide shoes use self-lubricating bearings (such as graphite-filled PTFE).

Exceptions: Older models or special environments (high temperatures) may require a small amount of high-temperature grease.

- Why do rollers wear prematurely?

Common causes:

Guide rail installation deviation (> 1mm/m).

Chronic unbalanced car loading (e.g., heavy objects are always placed on one side).

Using low-quality rollers (hardness does not meet the standard).

- Are roller guide shoes suitable for high-speed elevators? Applicability:

Low-speed elevators (≤1.75 m/s): Ordinary PU rollers are sufficient.

High-speed elevators (≥2.5 m/s): Nylon composite rollers with precision bearings are required.

- How can I reduce the noise of roller guide shoes?

Noise reduction measures:

Select guide shoe brackets with elastic pads (vibration-absorbing design).

Ensure smooth guide rail joints (polish the transition area).

Replace silent bearings.

English

English 中文简体

中文简体