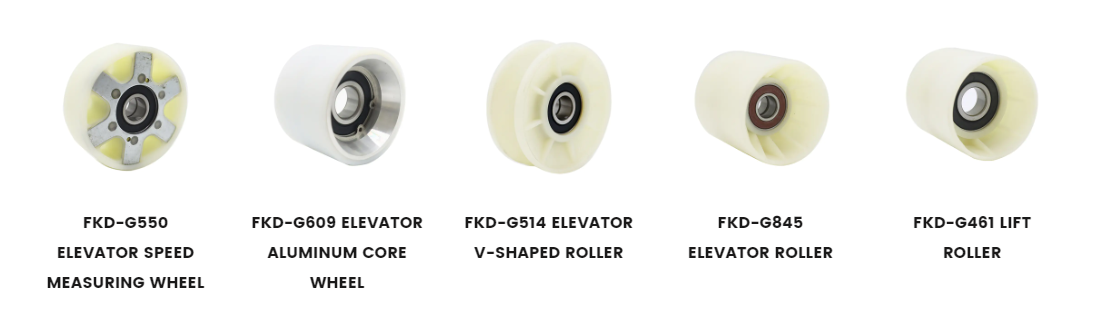

Escalators are indispensable means of transportation in cities, especially in crowded places such as shopping malls, stations, and airports. As an important component of escalators, rollers play a crucial role in their smooth operation. If escalator rollers malfunction, it can lead to the entire escalator breaking down, affecting passenger safety and the normal operation of the equipment. Therefore, regular inspection of the rollers is very important. So, how can you determine if there is a problem with escalator rollers?

1. Common Escalator Roller Faults and Symptoms

First, understanding the common types of escalator roller faults can help you detect potential problems earlier in daily use. Common faults include:

Wear and aging

Rollers bear the load and friction from the escalator for a long time, and may experience wear and aging after prolonged use. Aged rollers can lead to unstable escalator operation, abnormal noise, and even jamming.

Uneven roller wear

If a part of the escalator roller is severely worn, it may cause the escalator to tilt, shake, or become unstable during operation. This is usually caused by a lack of long-term maintenance, loose rollers, or quality issues.

Excessive noise

Under normal circumstances, escalator rollers should operate very smoothly without making significant noise. If you hear abnormal clicking, squeaking, or metal friction sounds, there may be a problem with the rollers, or poor lubrication or loose parts.

Roller detachment or damage

In extreme cases, if the escalator rollers are subjected to excessive wear or impact, they may detach or be severely damaged, affecting the normal operation of the escalator.

2. How to check if there is a problem with escalator rollers?

To ensure the long-term stable operation of escalators, regular inspection of the rollers is essential. Here are some common inspection methods:

Visual inspection

First, observe the appearance of the rollers. Check for any obvious cracks, wear, or deformation. If the surface of the roller is uneven or shows signs of wear, this may be an indication of a problem with the roller.

Listen to the sound

Start the escalator and carefully listen to the sound of the escalator during operation. If you hear unusual squeaking or metal grinding noises, it indicates that the rollers may lack lubrication or are worn out.

Manually check the roller movement

If possible, manually rotate the escalator rollers to check if they rotate smoothly. If the rotation is not smooth or there are noticeable jamming phenomena, it indicates that the rollers may be faulty and require maintenance or replacement.

Check if the rollers are securely installed

Use tools to check if the fixing screws or mounting components of the escalator rollers are loose. If the rollers are loosely installed, the escalator may be unstable or produce abnormal vibrations during operation.

Check the lubrication of the rollers

Ensure that the rollers have sufficient lubrication. Lack of lubrication will increase friction on the roller surface, accelerating wear. Therefore, checking the lubrication status of the rollers is very important.

3. Common Causes of Roller Failure

Understanding the common causes of roller failure helps prevent problems from occurring. The following are some common causes of escalator roller failure:

Long-term use without regular maintenance

Escalator rollers, like other mechanical components, require regular maintenance. Long-term use without lubrication and cleaning will accelerate roller wear and increase the risk of failure.

Environmental factors

Escalators are often in environments with large temperature differences, especially in high-temperature or humid places, which may affect the material of the rollers, leading to a decrease in performance.

Quality issues

Some low-quality rollers may have defects during the manufacturing process, making them more prone to wear or failure. Therefore, choosing a reliable brand and manufacturer is crucial.

Improper installation

If the rollers are installed improperly, it may lead to uneven wear, and in severe cases, even detachment. Therefore, correct installation methods and a professional maintenance team are very important.

4. How to Solve Escalator Roller Problems?

When you find a problem with the escalator rollers, you should immediately take measures to repair or replace them. The following are some common solutions:

Replace severely worn rollers

For rollers that are severely worn, the best solution is to replace them. You can contact professional maintenance personnel to disassemble and replace the rollers to ensure the normal operation of the escalator.

Lubrication and maintenance

If the rollers experience increased friction due to lack of lubrication, this can be solved by regularly lubricating the rollers. Professional maintenance personnel will select the appropriate lubricant based on the roller material and operating environment.

Adjusting the position and tightness of the rollers

For loose rollers, the mounting components need to be inspected, and the position and tightness of the rollers should be readjusted. If any damaged screws or fasteners are found, they should be replaced promptly.

Professional inspection and repair

If the specific cause of the malfunction is uncertain, it is recommended to contact a professional escalator maintenance company for a comprehensive inspection and repair. They will provide more professional diagnosis and solutions to ensure the safety and normal operation of the escalator.

Escalator rollers, as a critical component of the equipment, directly affect the stability and safety of the escalator. Regular inspection of the roller's appearance, rotation, and sound can effectively determine if there are any malfunctions. Prompt repair or replacement of faulty rollers can prevent accidents or equipment downtime caused by roller failure.

Maintaining the escalator rollers in good condition not only extends the equipment's lifespan but also ensures passenger safety. Therefore, checking and maintaining the rollers is a crucial aspect of both daily use and regular maintenance.

English

English 中文简体

中文简体