The short answer: An elevator guide shoe is a core guiding component that keeps the elevator car and counterweight aligned with the guide rails, directly affecting ride comfort, noise level, system stability, and long-term equipment safety. Choosing the right guide shoe can reduce vibration by up to 30–50% and extend rail and wheel service life.

Content

What Does an Elevator Guide Shoe Do?

The elevator guide shoe is mounted on the elevator car frame and counterweight frame. Its main role is to guide the elevator smoothly along the guide rails while minimizing friction and lateral movement.

Core Functions

- Maintain precise alignment between elevator and guide rails

- Reduce vibration and lateral sway

- Lower running noise

- Protect guide rails from abnormal wear

In high-speed elevators, guide shoe performance becomes even more critical. Even a 0.5 mm rail deviation can cause noticeable vibration without proper guiding components.

Types of Elevator Guide Shoes: Which One Should You Choose?

Different elevator applications require different guide shoe structures. The most common types include sliding guide shoes and roller guide shoes.

| Type | Best Application | Noise Level | Maintenance |

|---|---|---|---|

| Sliding Guide Shoe | Low-speed elevators | Medium | Requires lubrication |

| Roller Guide Shoe | High-speed elevators | Low | Low maintenance |

Industry data shows: Roller guide shoes can reduce operational noise by approximately 40% compared to traditional sliding types in high-rise buildings.

How Elevator Guide Shoes Improve Ride Comfort

Passenger comfort is strongly linked to vibration, acceleration stability, and noise. High-quality guide shoes play a major role in optimizing all three factors.

Key Comfort Improvements

- Reduced lateral vibration during travel

- Smoother acceleration and deceleration

- Lower mechanical noise and friction sound

In premium commercial elevators, vibration levels are typically controlled below 15 mg (milligravity units). Proper guide shoe selection is one of the main contributors to achieving this standard.

Material and Design Factors That Matter

Modern elevator guide shoes are designed with durability and performance in mind. Key design elements directly influence service life and reliability.

Important Technical Factors

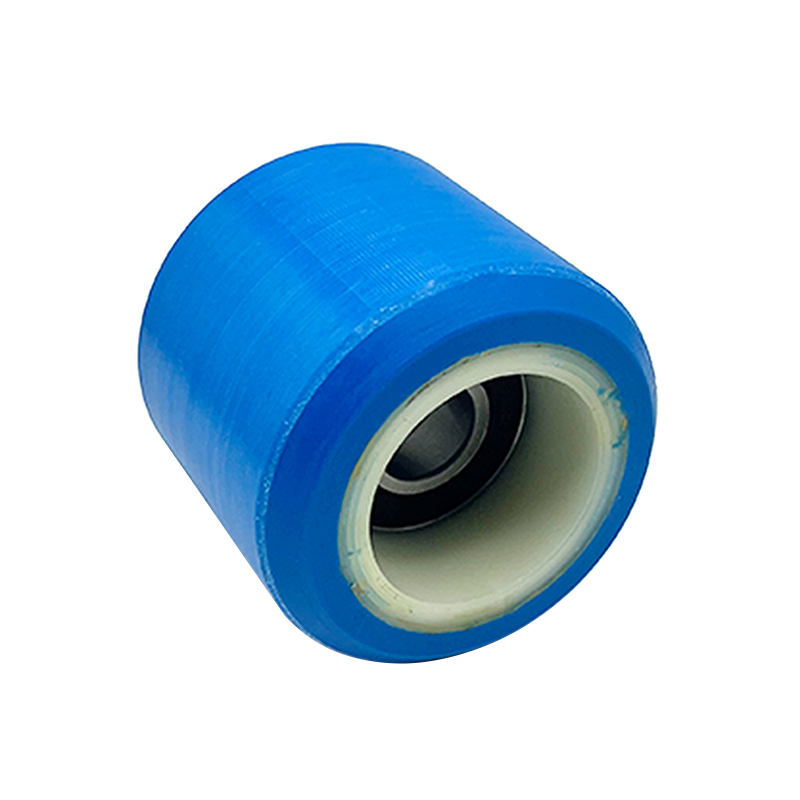

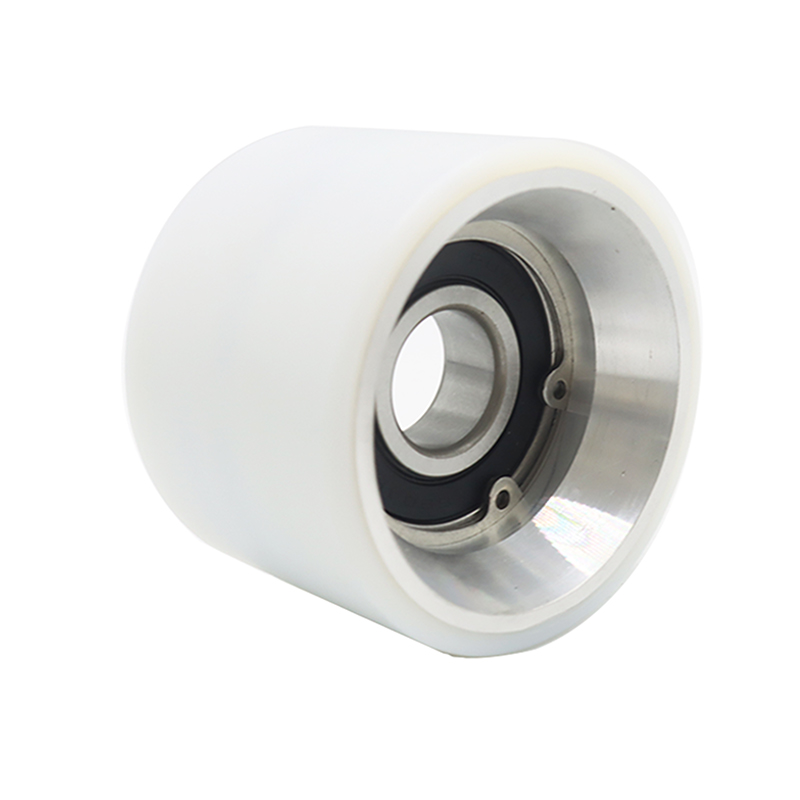

- Wear-resistant polymer or polyurethane liners

- Precision-machined roller bearings

- Adjustable spring or pressure systems

- Corrosion-resistant metal frames

High-grade materials can increase guide shoe lifespan by 2–3 times compared to basic plastic sliding blocks.

Where Are Elevator Guide Shoes Commonly Used?

Elevator guide shoes are used in almost all vertical transportation systems, with different configurations depending on speed and load requirements.

- Residential apartment elevators

- Commercial office buildings

- High-rise hotels and shopping malls

- Hospital and medical elevators

- Industrial freight elevators

High-speed elevators above 2.5 m/s almost exclusively use roller guide shoes for stability and comfort.

FAQ: Elevator Guide Shoe Common Questions

How often should elevator guide shoes be replaced?

Typically every 3–5 years, depending on usage frequency, load conditions, and maintenance quality.

Can worn guide shoes affect elevator safety?

Yes. Excessive wear can cause misalignment, increased vibration, and rail damage, potentially leading to unstable operation.

Are roller guide shoes better than sliding guide shoes?

For high-speed and high-comfort applications, roller guide shoes are generally better. Sliding guide shoes remain suitable for low-speed and cost-sensitive projects.

What is the most important factor when selecting a guide shoe?

The most critical factors are elevator speed, rail size compatibility, load capacity, and operating environment.

English

English 中文简体

中文简体