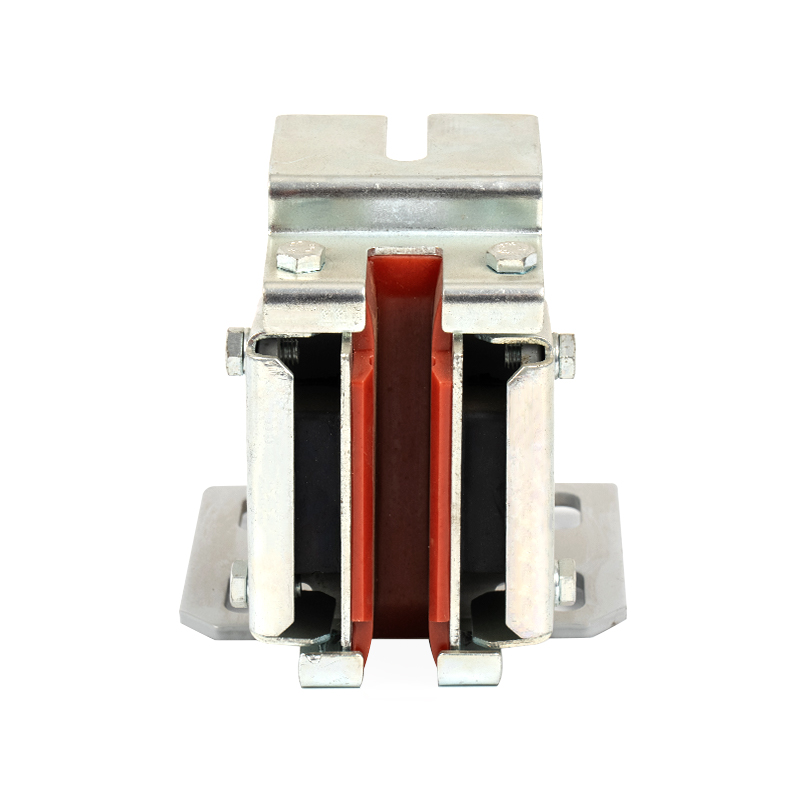

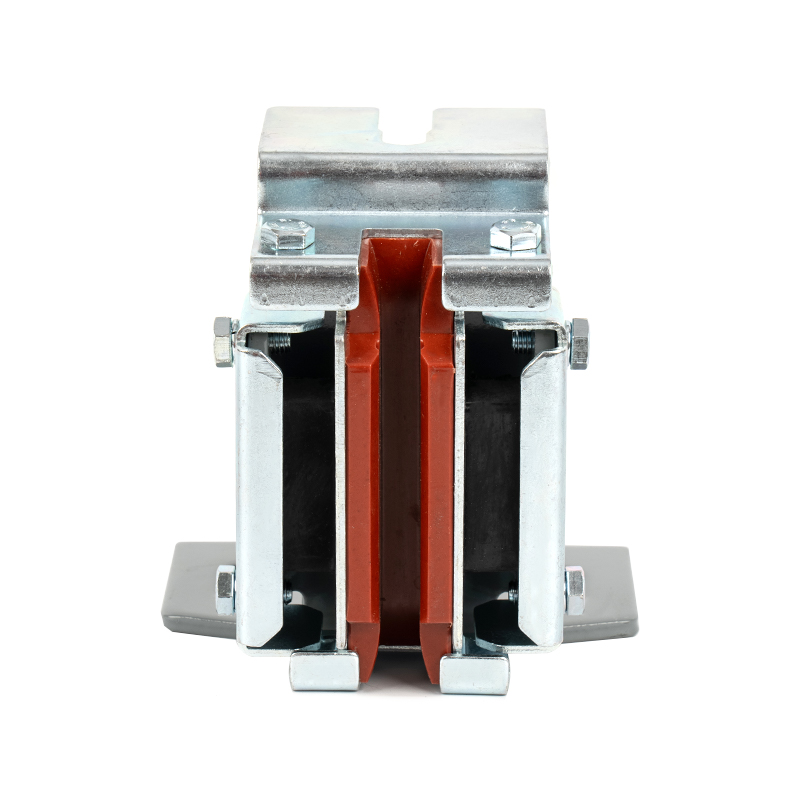

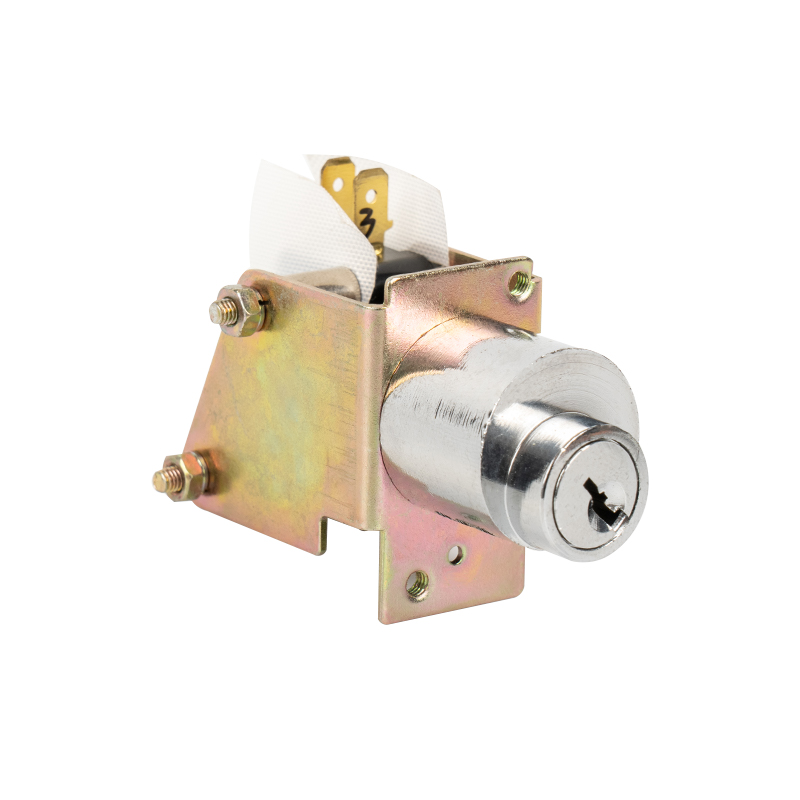

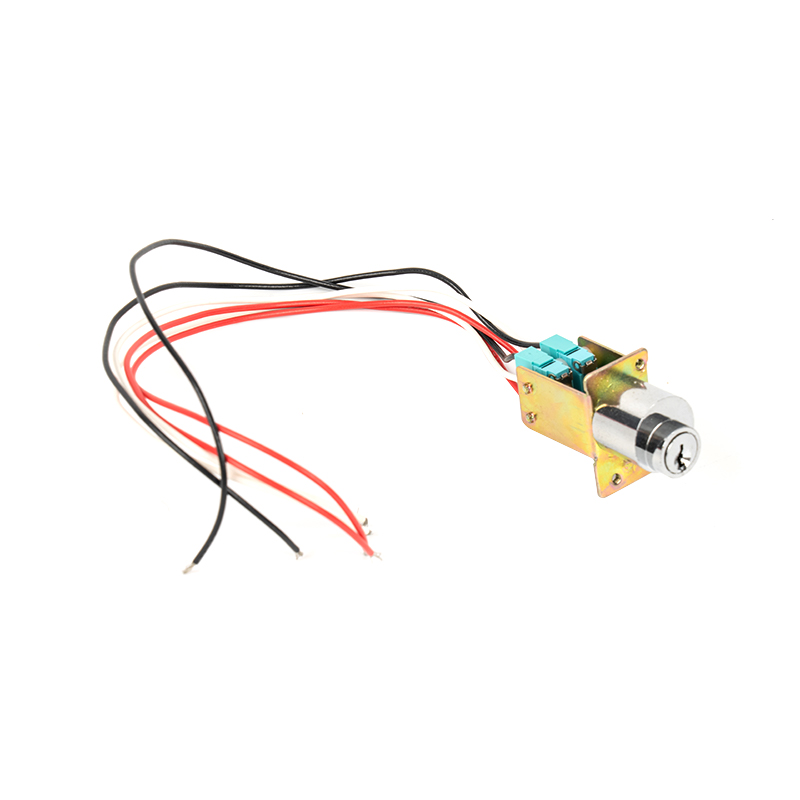

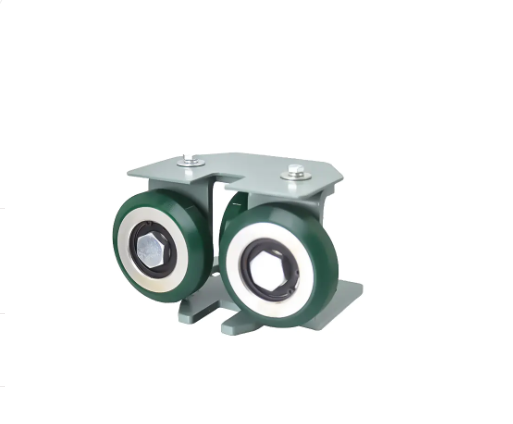

Elevator roller guide shoes are critical components that ensure the smooth operation of the elevator car and counterweight along the guide rails. Replacement is necessary when the following conditions occur to ensure safe, smooth, and comfortable elevator operation.

Content

1. Replacement Based on Wear

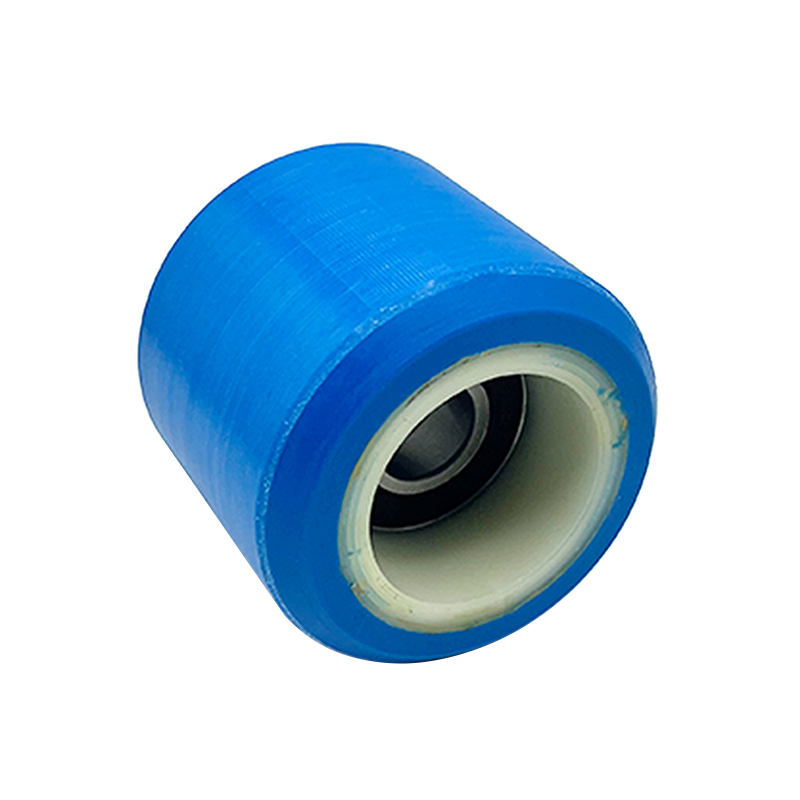

Excessive Diameter Wear: The outer ring of the roller, typically made of materials such as polyurethane or nylon, will continue to wear over time. When the roller diameter wear exceeds 1 mm (or, according to manufacturer standards, typically 5% of the original size), it must be replaced. This wear increases the gap between the roller and the guide rail, preventing effective guidance and vibration reduction.

Uneven Wear on the Wheel Rim: Normal roller wear should be uniform. If uneven wear, edge nibbling, chipping, or severe pitting is observed on the roller, it indicates uneven load or an installation problem and must be replaced immediately. Failure to do so will increase vibration and noise, and damage the guide rail.

2. Replacement Based on Physical Condition

A preliminary assessment can be made through visual inspection and manual inspection. Rubber aging, cracking, or hardening: Roller material ages over time and loses its elasticity. If you notice visible cracks or crazing on the roller surface, or if it feels unusually hard and lacks elasticity when pressed, its shock absorption performance has been significantly reduced and replacement is necessary.

Bearing damage: If you manually rotate the roller and feel it is sticking, stiff, noisy, or loose, it indicates that the bearing inside is damaged. Bearing damage causes the roller to slide instead of rolling, generating not only loud noise but also rapid wear on the roller and guide rail.

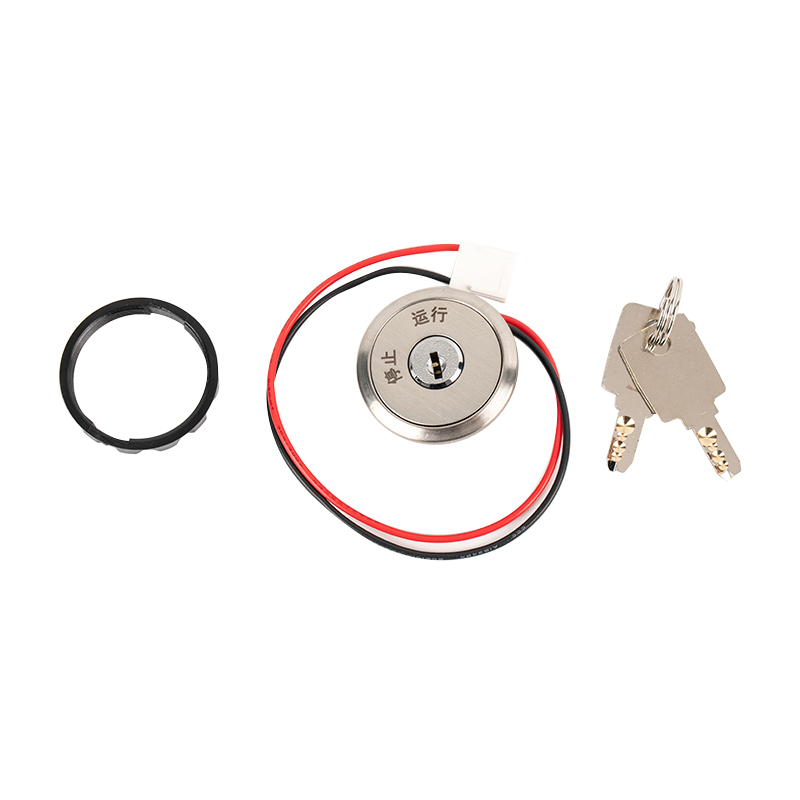

Roller detachment or structural damage: This is the most serious condition. If a roller is broken, deformed, or the mounting shaft is loose, the elevator must be immediately shut down and the entire guide shoe replaced. Otherwise, there is a high risk of derailment.

3. Replacement Based on Performance

The following symptoms often indicate poor condition of the roller guide shoe.

Abnormal noise: During elevator operation, especially during starting and stopping, a continuous "gurgling" sound, metallic friction, or regular clashing sounds may be heard from the elevator car or shaft. This is usually caused by uneven roller wear, bearing damage, or improper guide shoe adjustment.

Car Vibration and Shake: The elevator may feel unsmooth, with noticeable up-and-down or side-to-side shaking and vibration, significantly reducing comfort. This is usually because worn rollers no longer effectively adhere to the guide rails, losing their cushioning and guiding functions.

Poor Running Curve: The elevator may experience "slipping" (slight slippage) when leveling or reduced stopping accuracy, which may also be related to weakened guide shoe guidance.

4. Preventive Maintenance and Lifecycle

End of Life: Even if they appear intact, roller guide shoes have a designed lifespan (usually coinciding with the elevator's overhaul cycle, or approximately three to five years). During regular maintenance, maintenance personnel will recommend preventative replacement of older guide shoes to prevent unexpected failures.

Consequential Replacement: If an elevator experiences a major incident such as derailment, top-out, or bottom-out, the entire guide shoe system must be inspected and replaced, even if the guide shoes appear intact, as they may have hidden internal damage.

Important Notice:

Professional Operation: Identifying and replacing elevator roller guide shoes is a highly specialized and technical task that must be performed by elevator maintenance personnel holding a Special Equipment Operator Certificate. Never attempt this yourself.

Safety First: If you notice any of the above serious conditions (such as unusual noises, severe vibration, or structural damage), immediately stop using the elevator and notify a professional elevator maintenance company for inspection.

Regular Maintenance: The most effective way to prevent problems is to follow the elevator's regular maintenance schedule and have professionals perform measurements and inspections using specialized tools (such as vernier calipers) to prevent them from occurring.

English

English 中文简体

中文简体