Content

1. Escalator Roller Maintenance

Daily Inspection: A simple inspection and cleaning is required daily before and after the escalator is operated. This includes clearing dust and debris from the treads and handrails, and checking the handrails for smooth operation and any deviations.

Biweekly/Monthly Maintenance: Regular maintenance is required every two weeks to one month. This includes lubricating all parts that require lubrication and inspecting the step rollers (including the main pulleys and side pulleys) for wear and rotational flexibility. The handrail drive chain tension should also be checked and adjusted if loose.

Quarterly Maintenance: A more comprehensive inspection is required every quarter, which may include cleaning or replacing parts. For example, the step chain rollers may need to be disassembled, cleaned, and the bushing clearance measured every 4,000 hours.

Annual Maintenance: This annual maintenance cycle also includes inspecting, cleaning, or replacing parts. This is a good time to conduct a comprehensive inspection and evaluation of the rollers.

2. Cleaning and Lubrication

Cleaning: Regularly clean the escalator's treads and handrails to prevent the accumulation of dirt and debris. Use a cotton cloth to wipe the guide rails, scraping off hardened dirt with a scraper as needed. Be especially careful to avoid using water directly on electrical components and motors.

Lubrication: Regularly lubricate the escalator's moving parts to ensure smooth operation. Use the lubricant recommended by the equipment manufacturer and clean thoroughly before refueling. Avoid over-lubrication to prevent excess oil from contaminating the handrails or treads.

3. Inspection and Replacement Standards

Inspection Methods: Maintenance personnel will conduct a comprehensive assessment using a combination of methods, including listening, observing, touching, smelling, and inspecting. For example, "listening" checks for abnormal noises during operation; "observing" checks for smooth operation; "touching" checks for abnormal vibrations; and "smelling" checks for unusual odors. "Inspecting" involves precise testing using tools and instruments.

Replacement Thresholds: Rollers should be replaced promptly when the following conditions occur:

Severe flange wear: For example, check the handrail guide strip monthly for wear marks. Replacement is required if the wear mark exceeds the baseline by 2mm.

Roller cracking, deformation, or loss of elasticity.

Bearing damage: This can cause stalling, abnormal noise, or overheating.

Step chain rollers (such as nylon rollers) are severely worn.

Step main and auxiliary rubber wheels (i.e., main and side wheels) are incomplete or damaged.

4. Safety Instructions

Maintaining escalators is a highly specialized task, and safety must be prioritized.

Professionals: Escalator maintenance must be performed by professionals who have received specialized training and passed certification.

Safety Guarding: Before maintenance, safety guardrails and "Under Maintenance, Do Not Use" signs must be installed at upper and lower entrances and exits to effectively prevent entry.

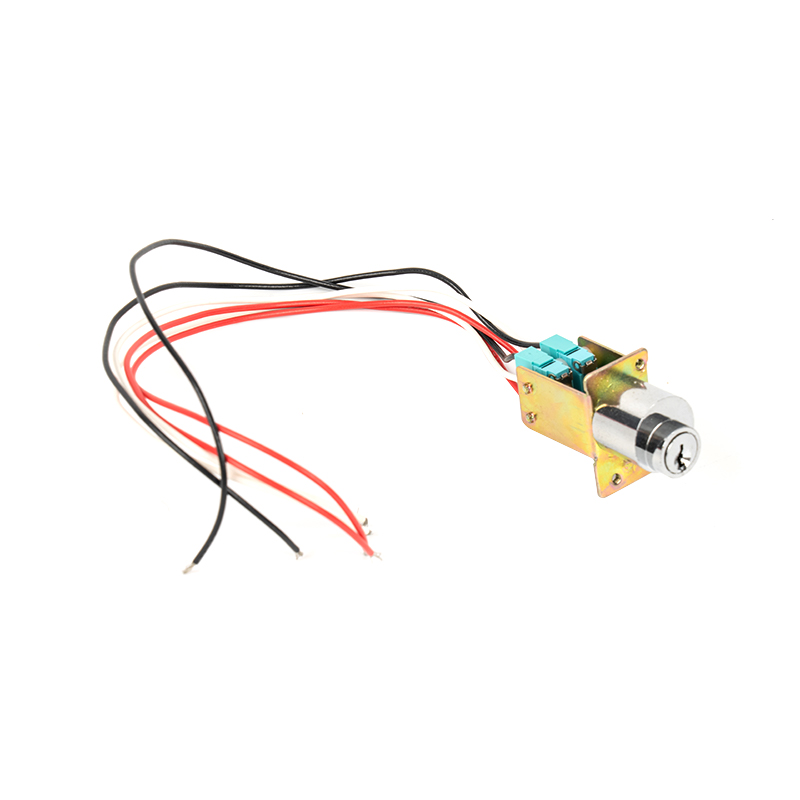

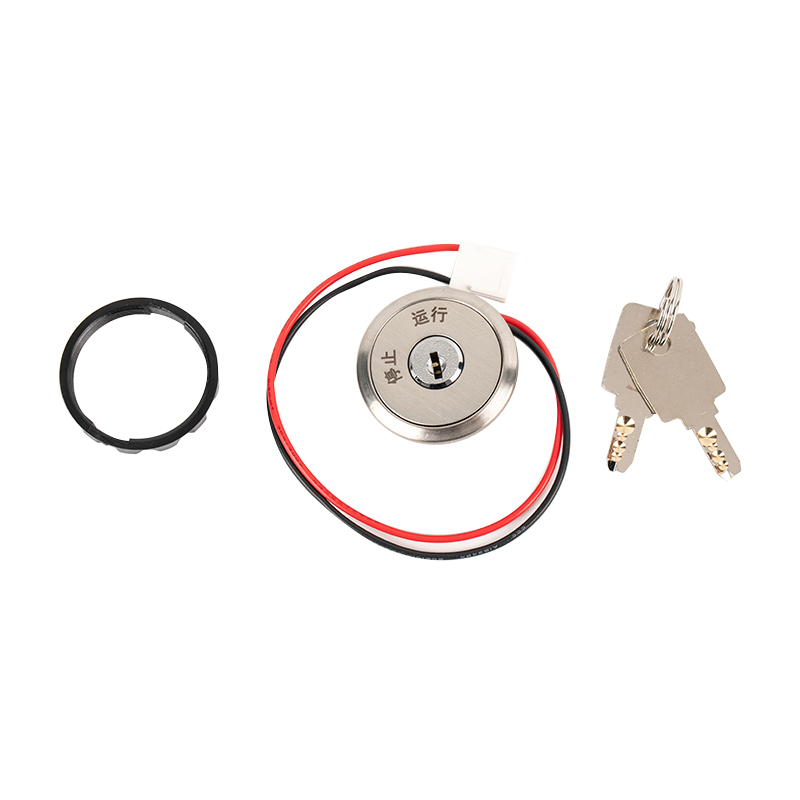

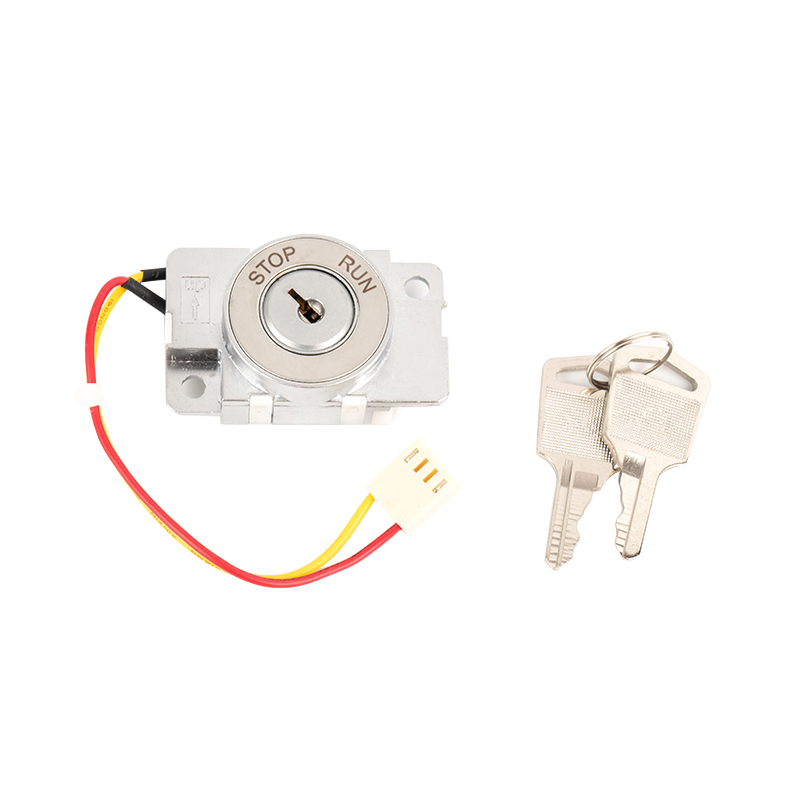

Power Disconnect Sign: When necessary, turn off the main power switch and display a "Under Maintenance, Do Not Close" sign, especially when personnel are working inside the stairway. Enable maintenance mode: switch the escalator to the "maintenance" state and use the maintenance box to control the escalator's jog operation.

Maintenance points table for escalator rollers:

| Roller Types | Key Maintenance Points | Common Potential Problems |

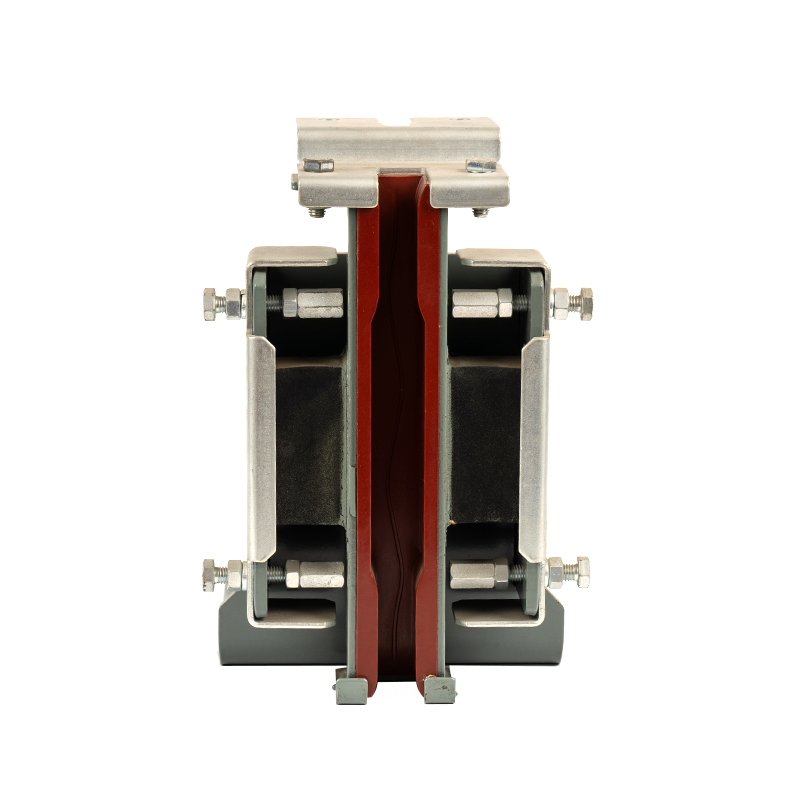

| Step Main Wheels | Check wheel flange wear, smooth rotation, and bearing condition; ensure the fastening bolts are not loose. | Excessive wheel flange wear, bearing seizure, or abnormal noise. |

| Step Side Wheels | Check wheel flange wear and clearance with the guide rail (to prevent uneven wear); maintain adequate lubrication. | Wear flange and improper clearance can cause step deviation. |

| Handrail Rollers | Check wheel flange wear and surface cleanliness (no oil or grease); ensure proper tension and secure installation. | Wear flange and improper tension can cause handrail slippage. |

| Drive Chain Rollers | Check nylon or metal rollers for wear; ensure proper tension. | Wear and improper tension can cause noise or chain skipping. |

English

English 中文简体

中文简体