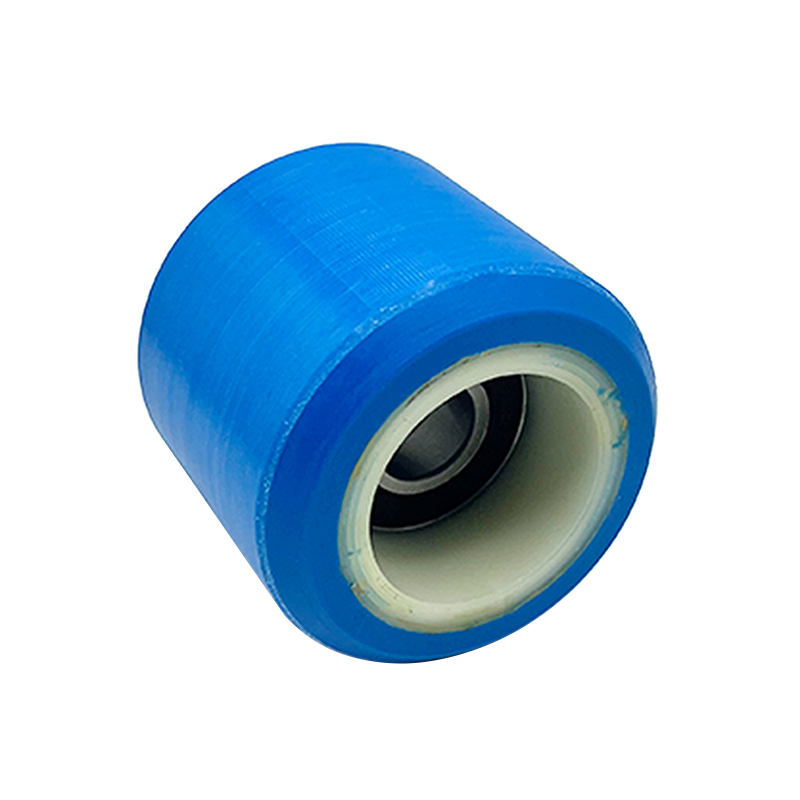

Elevator roller guide shoes are a crucial component of the elevator guide rail system, primarily used to guide the elevator car and counterweight along the guide rails for smooth operation while reducing friction and vibration.

Content

1. Functions of Elevator Roller Guide Shoes

Guidance and Stable Operation

Precise Positioning: The rubber or polyurethane rollers of the roller guide shoes adhere closely to the sides of the guide rails, ensuring vertical movement of the car/counterweight along the rails and preventing lateral deviation or sway.

Offset Load Resistance: When the elevator is unevenly loaded (such as when passengers are concentrated on one side), the roller guide shoes adapt to pressure distribution and maintain operational stability.

Shock and Noise Reduction

Vibration Absorption: The elasticity of the rubber coating absorbs impact from uneven guide rails and rail joints, reducing car vibration and improving ride comfort (noise is reduced by over 50% compared to traditional sliding guide shoes).

Silent Design: Rolling friction replaces sliding friction, significantly reducing metallic friction noise, making it suitable for noise-sensitive environments such as high-end residences and hospitals.

Reduced Friction and Energy Consumption

Rolling Friction Advantage: The coefficient of friction of roller guide shoes is only 1/10 that of sliding guide shoes, reducing the load on the elevator drive motor and saving approximately 5%-15% in energy consumption.

Lubrication-Free Maintenance: Traditional sliding guide shoes require regular grease application, while roller guide shoes rely on the self-lubricating properties of rubber/polyurethane, reducing maintenance costs.

Extended Guide Rail Life

Protecting the Guide Rail Surface: The hardness of rubber or polyurethane rollers (typically 70-90 Shore A) is lower than that of metal rails, preventing wear and scratches.

Adaptive Guide Rail Error: Minor guide rail installation deviations or deformation (e.g., straightness within ±3mm) can be tolerated, reducing the stringent requirements for guide rail accuracy.

Suitable for High-Speed Elevators

High-Speed Stability: Roller guide shoes are standard equipment for high-speed elevators (>2.5m/s). Their low friction and vibration resistance ensure smooth and jitter-free acceleration and deceleration of the elevator car. Temperature resistance: High-quality polyurethane rollers can work in an environment of -30℃~+80℃, avoiding material failure caused by extreme temperatures.

2. Common problems of elevator roller guide shoes

Abnormal Roller Wear

- Unilateral Wear (Severe Wear on One Side)

Phenomenon: One side of the roller wears significantly faster than the other, which may be accompanied by car jitter.

Causes:

The guide rail is not installed vertically or is twisted (e.g., plumb deviation >1mm/m).

The car frame is deformed or the guide shoe bracket is unevenly stressed.

The roller spring pressure is improperly adjusted (excessive pressure on one side).

Solution:

Use a laser alignment tool to check the guide rail verticality and adjust it.

Realign the car frame or replace the deformed bracket.

Readjust the spring pressure to ensure even stress on all rollers.

- Excessive Groove Wear

Phenomenon: The groove depth on the roller contact surface exceeds 3mm (the standard groove depth for a new roller is approximately 1-2mm).

Causes:

Hard impurities such as sand and metal shavings are present on the guide rail surface.

The roller material is not sufficiently hard (e.g., low-quality polyurethane).

The elevator operates at an excessively high frequency (e.g., a shopping mall elevator operates over a thousand times daily). Solution:

Clean the guide rails and apply guide oil (only for sliding guide shoe rails; roller guide shoe rails should be kept dry).

Replace high-hardness rollers (such as polyurethane wheels with a Shore A hardness of 90A).

For elevators with high usage, shorten the inspection cycle (every three months).

Rubber/Polyurethane Material Failure

- Surface Cracking or Hardening

Symptom: Cracks appear on the roller surface, loss of elasticity, and a "creaking" noise during operation.

Causes:

Extended UV exposure (such as in glass-shaft elevators).

Ozone or chemical corrosion (lubricant or cleaning agent leaks from the machine room).

Natural aging of the material (usually 5-8 years).

Solution:

Replace with UV-resistant material (such as EPDM rubber).

Avoid using solvents containing benzene or ketone for cleaning.

Inspect regularly, and replace all aging rollers (avoid mixing old and new).

- Rubber Delamination

Symptom: The outer rubber layer of the roller separates from the metal wheel core. Cause:

Defective bonding process (e.g., glue not meeting ISO 813 standards).

Overloaded operation causing excessive shear stress on the rubber layer.

Solution:

Select integrally cast polyurethane rollers (without a bonding interface).

Check the accuracy of the elevator load sensor.

Mechanical Structure Problems

- Bearing Seizure or Abnormal Noise

Symptom: The roller rotates stiffly, accompanied by a metallic grinding sound.

Cause:

Seal failure allowing dust ingress (common in construction site elevators).

Grease drying out or contamination (e.g., mixing with cement powder).

Solution:

Use bearings with IP54 protection rating.

Clean the bearings annually and refill with high-temperature lithium-based grease.

- Spring Failure

Symptom: Insufficient or excessive contact pressure between the roller and the guide rail.

Cause:

Spring rust (humid environment).

Fatigue deformation (over 100,000 compression cycles).

Solution:

Replace the spring with stainless steel. Use a pressure gauge to check the spring force (the standard value is usually 150~200N/wheel).

3. Daily inspection and maintenance

|

Maintenance Items |

Inspection Content |

Standards/Requirements |

Remedy |

|

Roller Appearance Inspection |

Surface Cracks, Peeling, Deformation, Groove Wear Depth |

Wear ≤ 3mm, no visible cracks |

Exceeding the standard requires replacement; minor cracks can be used temporarily, but the inspection interval should be shortened. |

|

Rotational Flexibility |

Manually rotate the roller to check for binding or abnormal noise. |

Smooth rotation, no metallic friction. |

Bearing binding requires cleaning and lubrication; severe abnormal noise requires replacement of the bearing or roller. |

|

Spring Pressure |

Check the spring for rust, deformation, and uniform pressure. |

Pressure 150-200N/roll, no plastic deformation. |

Uneven pressure requires adjustment; rust or deformation requires spring replacement. |

|

Guide Rail Contact |

Full contact between the roller and the guide rail, and any uneven wear. |

Uniform contact surface, no unilateral wear. |

If uneven wear occurs, check the guide rail verticality or car frame deformation. |

|

Bolt Tightness |

Check the guide shoe bracket and axle fixing bolts for looseness. |

The torque should meet the manufacturer's specifications (e.g., 30-50 Nm). |

Retighten and mark the bolts to prevent loosening. |

English

English 中文简体

中文简体