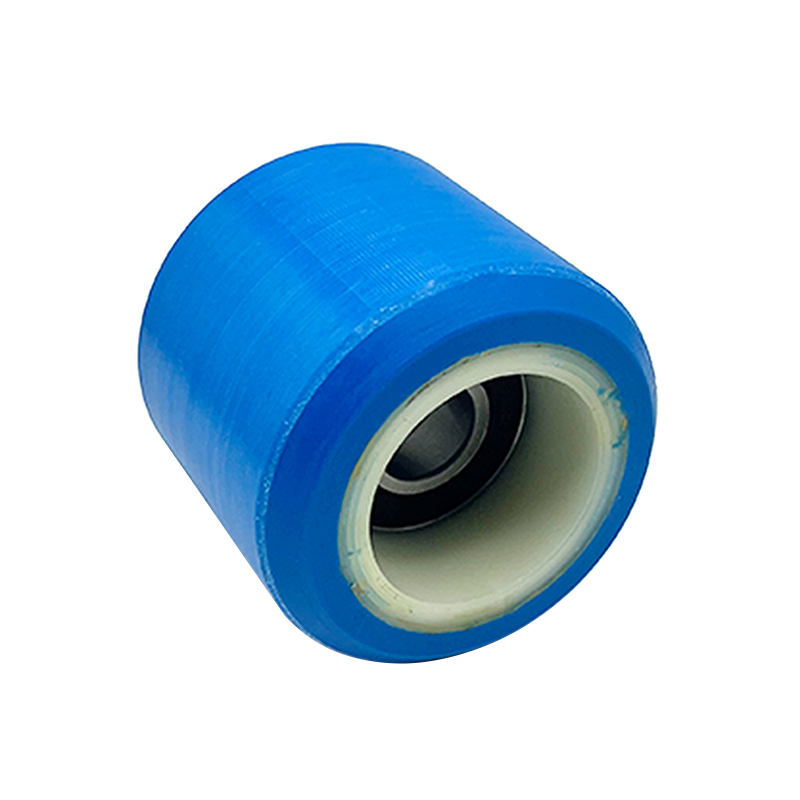

1. Materials and Design

The service life of elevator guide shoes mainly depends on the wear resistance of the shoe lining material. Common materials include nylon, hard plastic, glass fiber reinforced polytetrafluoroethylene, etc. The hardness and surface roughness of the guide rail directly affect the friction loss. Too high surface roughness will accelerate the wear of the shoe lining, and too low surface roughness will easily cause adhesive wear due to insufficient lubrication. The deviation of the straightness of the guide rail or the large gap between the joints will cause uneven force on the guide shoe and aggravate local wear.

2. Operating conditions

When the elevator is frequently overloaded or the car is overloaded, the normal pressure on the guide shoe increases, and the accumulated friction heat leads to accelerated material fatigue. The counterweight guide shoe is usually worn at a lower rate than the car guide shoe due to long-term constant load. The life of the guide shoe with high frequency of use is usually shortened by 30%-50% compared with residential elevators.

3. Influence of the external environment

The elevator guide shoe will accelerate the oxidation failure of the grease in a high temperature environment, and the low temperature will cause the nylon lining to become brittle and crack. A humid or salt spray environment can easily cause metal parts to rust, and a dusty environment requires the cleaning cycle to be shortened to once a month. Acidic gases in chemical sites corrode the surface of the guide rails, so stainless steel guide rails or special coated guide shoes are required.

English

English 中文简体

中文简体