1. Inspection and cleaning

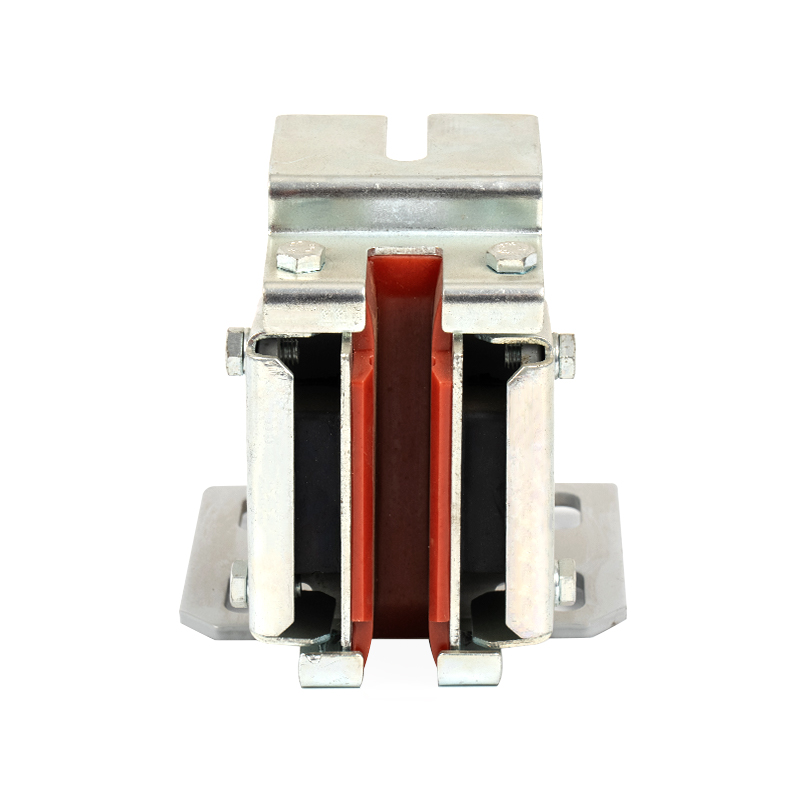

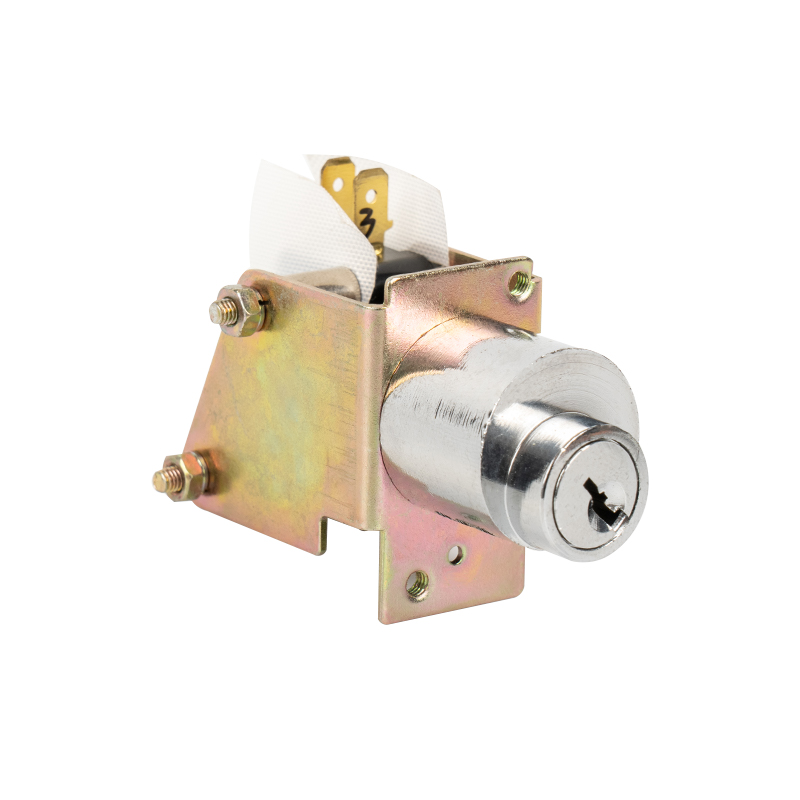

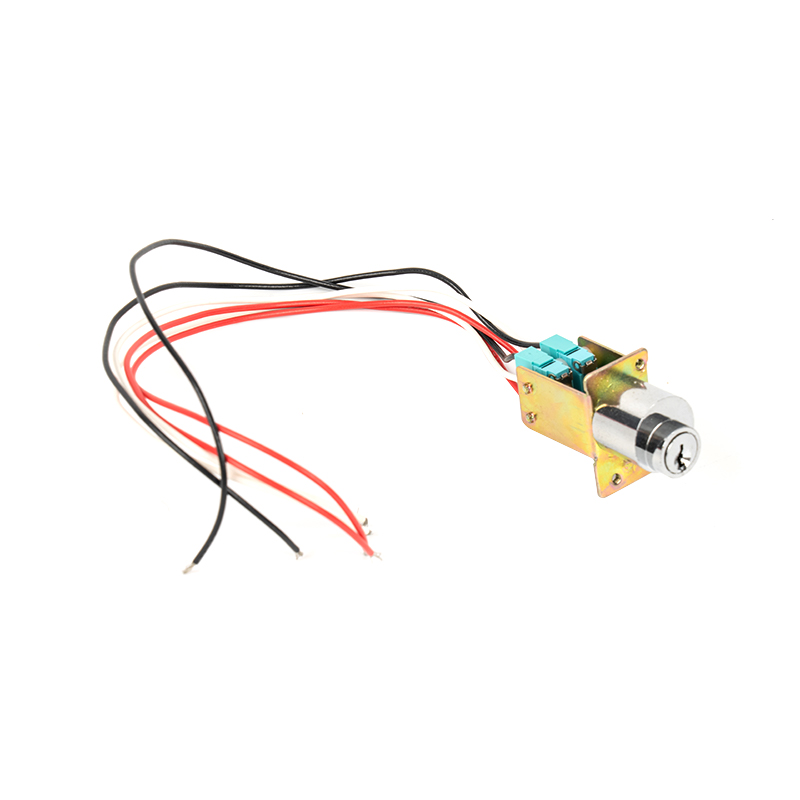

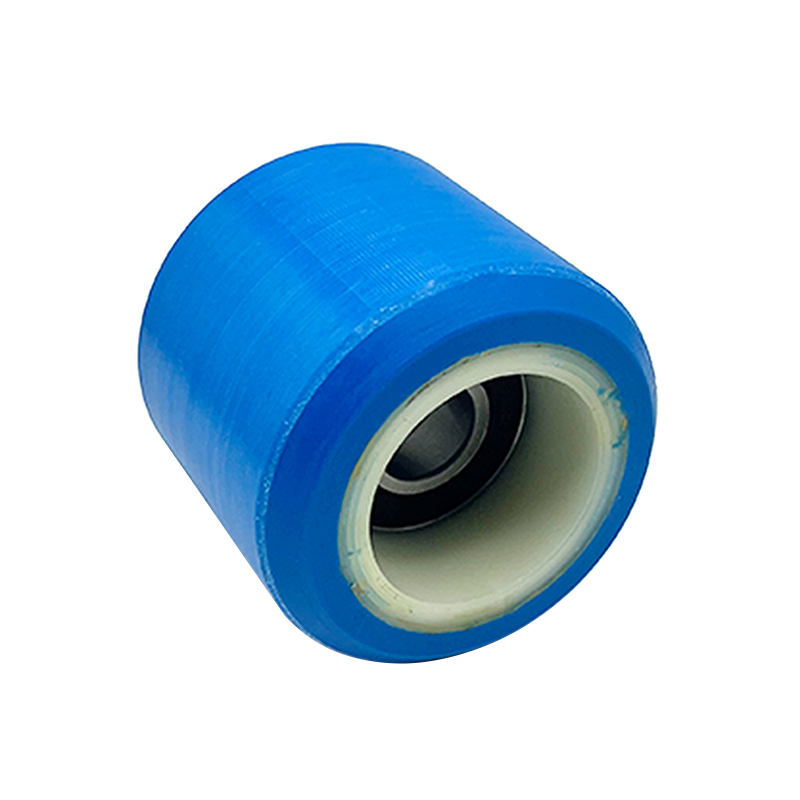

Regularly check whether the terminal is loose or oxidized, and focus on checking the connection status of the power line, control line and signal line to ensure that there is no false connection or short circuit. Use electronic cleaner to clean the carbide on the contact surface to prevent poor contact from causing circuit abnormality. Regularly wipe the inside of the keyhole with anhydrous alcohol to remove dust or oil, and inject graphite powder into the keyhole for lubrication to avoid plugging and unplugging. Check the degree of wear of the rotating paddle. If metal fatigue or deformation occurs, it needs to be replaced in time.

2. Component lubrication treatment

Apply a small amount of silicone-based grease (not engine oil) to the mechanical parts such as the spring and lock core of the lift key switch every six months to prevent grease from absorbing dust. Switches with a protection level lower than IP65 need to spray rust inhibitor on the metal surface to prevent rust in a humid environment. Check whether the waterproof rubber ring is aging and cracking, especially outdoor equipment needs to replace the sealing ring every quarter to prevent water vapor from invading and causing short circuits.

3. Operation Specifications and Usage Management

When inserting and removing the key, keep the key at a vertical angle to avoid deformation of the lock core caused by lateral force. The rotation force should be controlled within the range of 0.5-1.5N·m. Do not insert or remove the key while it is powered on to prevent arc erosion of the contacts. Before operation, make sure that the equipment is in a stationary state. The key should be kept by a certified safety manager, and a registration account should be established to prevent unauthorized operation.

English

English 中文简体

中文简体