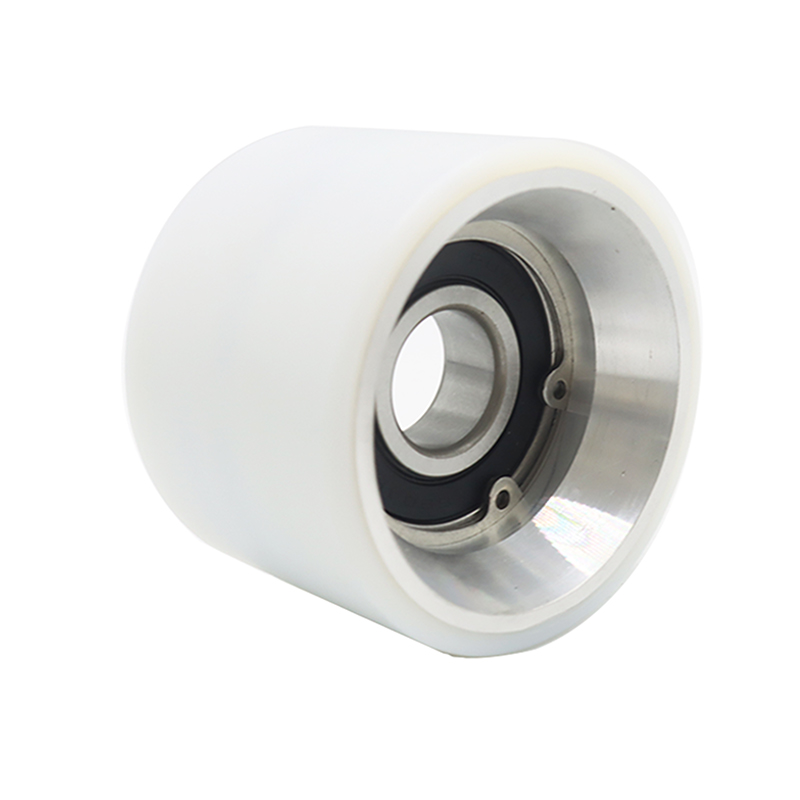

Escalator rollers are one of the core transmission components of an escalator, supporting the step chain or pallets and ensuring smooth, low-noise operation. Their performance directly impacts the comfort, safety, and service life of the escalator.

1. Core Functions of Rollers

Load-Bearing: Distributes the load of steps and passengers, reducing wear on the metal structure.

Guiding: Rolls along the guide rails, ensuring the precise trajectory of the step chain and preventing deviation.

Vibration and Noise Reduction: Buffers vibration during operation, improving ride comfort.

2. Common Faults and Maintenance of Escalator Rollers

Typical Faults

Abnormal noise: Bearing damage, wheel surface wear, or insufficient lubrication.

Increased vibration: Roller eccentricity, cracked rubber coating, or loose installation.

Step deviation: Uneven roller wear or misaligned guide rails.

Maintenance Tips

Regular Lubrication: Re-lubricate with grease (such as lithium-based grease) every 3-6 months, paying particular attention to the bearings. Wear Inspection: Wheel tread grooves exceeding 2mm or cracks require replacement.

Guide Rail Cleaning: Avoid grit and oil, which accelerate roller wear.

3. Replacement Standards and Precautions

Escalator Roller Replacement Standards

Wear Limits

Tread Wear: Replacement is required when the roller tread (contact surface with the rail) is worn more than 20%-30% of its original thickness (refer to manufacturer's standards for details) or when visible grooves or cracks appear.

Ring Wear: Replacement is required when wear on the wheel flange (guide edge) causes excessive clearance between the wheel and the rail, potentially posing a risk of derailment.

Abnormal Operation

Abnormal Noise or Vibration: A sharp noise or irregular vibration during roller rotation may be caused by bearing damage or shaft eccentricity.

Stuck Roller: Stiff rotation or resistance or sticking when manually turned indicates bearing or wheel damage.

Appearance Defects

Rubber Aging: Cracks, hardening, or peeling on the rubber wheel surface may indicate loss of shock absorption and grip.

Metal Wheel Deformation: Deformation, rust, or cracking of the metal wheel body.

Life Cycle

Even if there is no noticeable wear, preventive replacement is recommended based on the manufacturer's specified cycle (usually 2-5 years) or operating hours (e.g., 10,000 hours).

Escalator Roller Precautions

Safety Operation

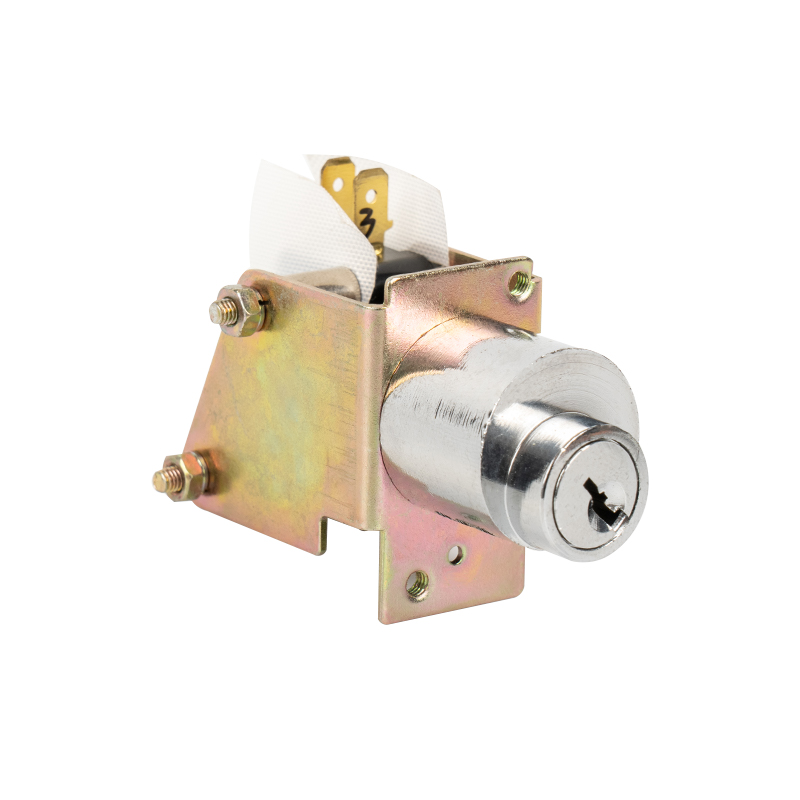

Power-off Tagout: Before replacement, power must be disconnected and a warning sign must be hung to prevent accidental startup.

Safety Measures: Use safety ropes to secure escalator components to prevent them from falling during disassembly.

Accessory Compatibility

Model Consistency: New rollers must exactly match the original manufacturer's specifications (diameter, material, and bearing type) to avoid uneven force after installation.

Group Replacement: Rollers in the same area are recommended to be replaced simultaneously to maintain balanced operation.

Installation Specifications

Torque Calibration: Fastening bolts must be tightened to the standard torque. Overtightening may damage the bearing, while over-loosening may cause loosening.

Alignment: After installation, check the contact surface between the roller and the guide rail for uniformity, and adjust the guide rail position if necessary.

Testing and Acceptance

No-load Test: Manually crank the roller to check for smooth rotation without friction or abnormal noise. Load Operation: After powering on, conduct a low-speed test run to observe vibration and noise, then gradually increase the speed to the rated speed.

Records and Maintenance

Replacement Records: Detailed records of replacement time, location, and batch number are kept for quality tracking.

Regular Lubrication: Non-maintenance-free bearings require regular lubrication with the specified grease (such as lithium-based grease).

English

English 中文简体

中文简体