1. Mechanical locking principle: physical anti-pry and position verification

The mechanical design of the elevator triangular lock is the basis of its safety, which mainly relies on the following mechanisms:

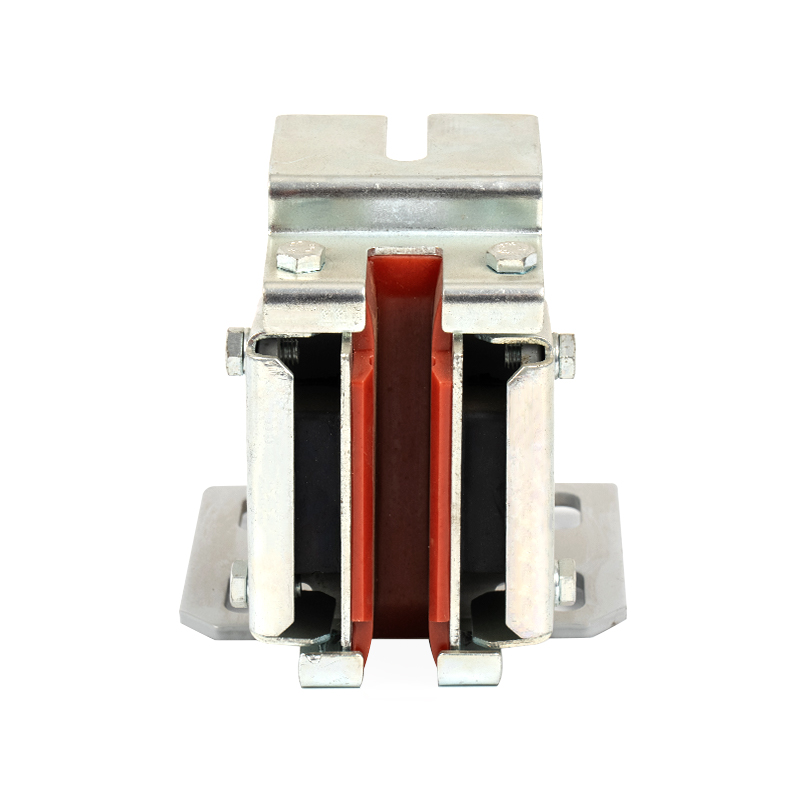

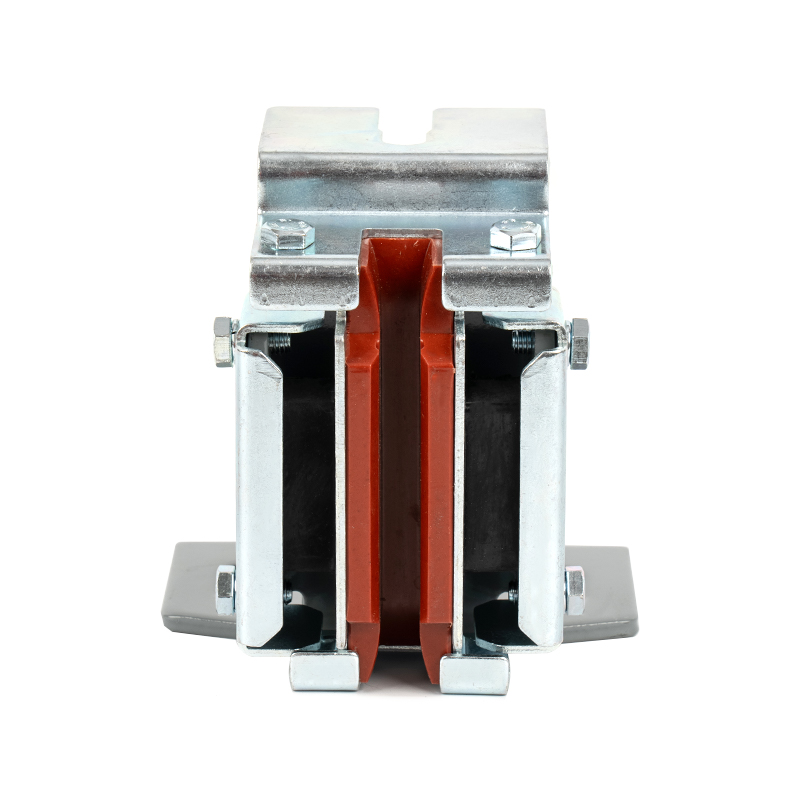

Two-way lock tongue structure

The triangular lock adopts the design of the interlocking of the fixed door hook and the movable door hook. The movable door hook realizes the tilting action through the roller and the shaft to ensure that the lock tongue is allowed to move horizontally only when the car is level. This structure can resist the impact of external forces above 2000N and prevent human prying.

Floor door position verification

According to the requirements, the triangular lock needs to be automatically locked after the car leaves the leveling area. The mechanical linkage device detects the position of the car through the guide rail slider. If the car is not aligned with the floor door, the lock tongue will be stuck in the fixed groove to force the door leaf to be closed.

Anti-fall protection

When operating the triangular key, you must follow the process of "confirming the position of the car first, then slowly unlocking" to avoid falling due to misoperation. Some high-end models also have a secondary lock buckle, which automatically triggers the brake when the door gap exceeds 100mm.

2. Electrical safety circuit: double verification and fault protection

The electrical system of the triangular lock is linked with the elevator control cabinet to form multiple protections:

Safety circuit series

The state of the lock tongue is connected to the safety circuit through a micro switch. Once the door lock is detected to be not fully engaged, the elevator stops running immediately.

Electronic monitoring upgrade

The new intelligent triangular lock is equipped with an RFID chip. Only the keys of authorized personnel (such as those holding special equipment operation certificates) can trigger unlocking, and upload the operation records to the cloud in real time.

Power failure emergency mechanism

Even if the elevator loses power, the mechanical lock tongue can still remain locked through the spring mechanism. In emergency rescue, the triangular key can be manually unlocked, but the shaft lighting must be activated simultaneously to avoid the risk of blind operation by rescuers.

3. Emergency management mechanism: authority control and operation specifications

The safety of the triangular lock not only depends on hardware, but also requires strict management system support:

Key classification control

The triangular key is only for use by certified personnel (such as elevator maintenance workers and safety managers), and the use information must be registered.

Standardized operation procedures

Before unlocking: confirm the position of the car (observe through the door gap or floor display)

During unlocking: keep the body's center of gravity stable and avoid sudden force

After unlocking: return the key immediately and fill in the record book

Regular maintenance and testing

The lock tongue needs to be tested for durability 100,000 times every quarter to check for wear and elastic failure

English

English 中文简体

中文简体