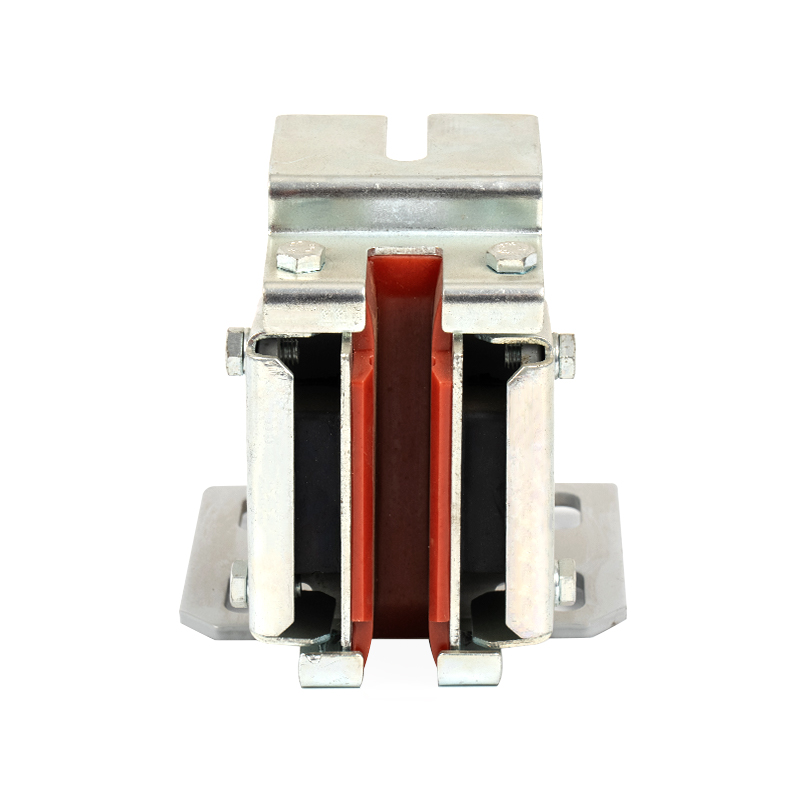

Elevator roller guide shoes: key components to ensure the smooth operation of elevators

1. Product function: Guardian of stable elevator operation

Elevator roller guide shoes are an important part of the elevator guide rail system, and they mainly undertake three core functions:

Precise guidance

As the contact medium between the elevator car and the guide rail, it ensures that the elevator runs smoothly along the vertical track and prevents horizontal deviation. When modern high-rise elevators are running, roller guide shoes can control the swing amplitude of the car within ±5mm.

Vibration buffering

The elastic support structure absorbs the impact force when the elevator starts and stops, reducing the bumpy feeling of passengers. Test data shows that high-quality roller guide shoes can reduce vibration transmission by more than 60%.

Safety redundancy

In sudden situations (such as earthquakes or guide rail deformation), the mechanical structure of the roller guide shoe can provide additional support to prevent the car from getting stuck or derailing, and buy time for emergency rescue.

2. Working principle: Precision design of mechanical engineering

Core structure composition

Roller assembly: Polyurethane or nylon composite wheel body, wear resistance coefficient of 0.3-0.5 (dry friction conditions)

Support arm: alloy steel material, load-bearing up to 150% of the full load weight of the car

Elastic adjustment system: built-in spring or hydraulic buffer device, dynamically adapt to the change of guide rail spacing

Operation mechanism

Vertical movement: The roller rolls along the T-slot of the guide rail, and the friction coefficient is only 1/3 of the sliding guide shoe (0.05-0.08 vs 0.15-0.2)

Horizontal limit: The rollers on both sides are arranged symmetrically in a V shape to form a self-centering structure

Dynamic compensation: The spring preload automatically adjusts the contact pressure between the roller and the guide rail (usually maintained at 20-30N)

3. Precautions for use: Key points of operation and maintenance

Installation specifications

Coaxiality calibration: The deviation between the center line of the roller and the working surface of the guide rail must be less than 0.5mm/m

Preload test: Use a torque wrench to adjust to the manufacturer's specified value (usually 15-25N·m)

Lubrication management: It is strictly forbidden to add lubricating oil to maintenance-free rollers, and special grease must be applied monthly to traditional rollers

Daily inspection

Wear monitoring: Polyurethane rollers must be replaced if the thickness wear exceeds 3mm

Abnormal sound diagnosis: Sharp metal sounds may indicate bearing damage, and dull impact sounds are mostly caused by spring failure

Gap measurement: Use a feeler gauge to check the gap between the roller and the guide rail. If it exceeds 2mm, it needs to be readjusted

Response to special working conditions

|

Scenario |

Countermeasures |

Risk warning |

|

Extreme temperatures |

Use wide temperature grease (-30℃~120℃) |

Low temperature embrittlement/high temperature softening |

|

Coastal area |

Monthly check for salt spray corrosion of stainless steel fasteners |

Stress corrosion cracking caused by chloride ions |

|

High frequency use |

Check bearing clearance after every 30,000 runs |

Increased radial runout caused by ball wear |

Life management

General replacement cycle: 5-8 years for polyurethane rollers, 10-12 years for bearing components

Scrap criteria: cracks, permanent deformation or hardness reduction of more than 15%

English

English 中文简体

中文简体