Elevator roller guide shoes typically don't require "washing" like a car wash, but they still need regular, professional "inspection and cleaning maintenance" during use.

Directly washing them with water or inappropriate cleaning agents can actually cause damage.

1. Core Principle: Why Can't They Be Cleaned Randomly?

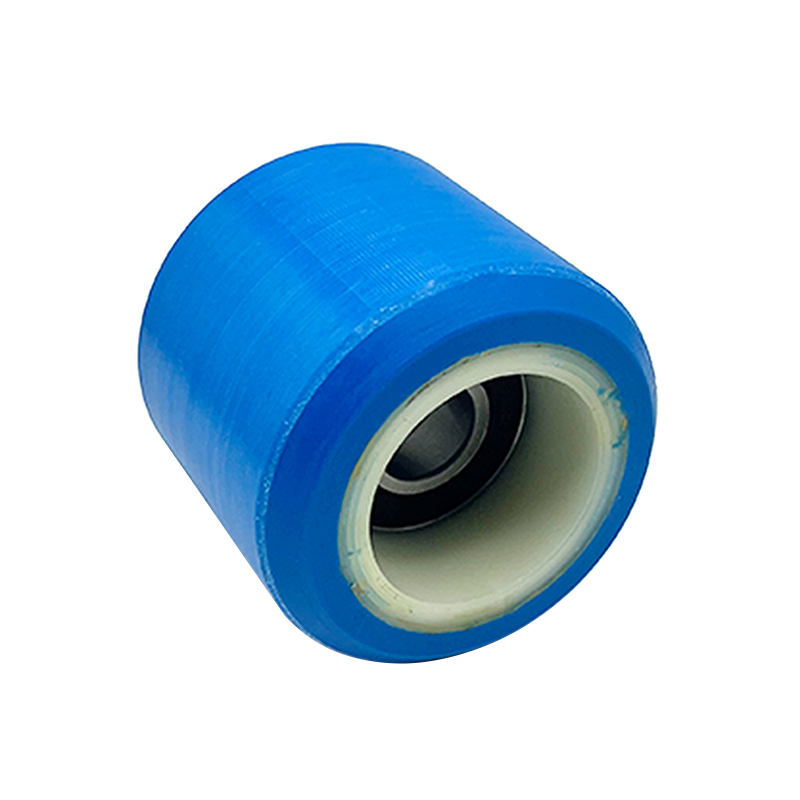

Elevator roller guide shoes are the "feet" that allow the elevator car and counterweight to run smoothly along the guide rails. Their core component is a rubber or polyurethane roller, and its working condition directly affects the elevator's comfort, noise level, and lifespan.

Damage to Bearings: The rollers contain precision bearings. If washed directly with water or cleaning agents, the liquid can easily seep into the bearings, washing away the original lubricant, leading to poor lubrication, rust, and seizing. Once the bearings are damaged, the rollers cannot rotate properly, becoming "dragging wheels," producing severe friction, abnormal noise, and vibration.

Rubber/Polyurethane Aging: Many cleaning agents contain chemical solvents that corrode the rubber or polyurethane materials on the roller surface, causing them to harden, crack, and lose elasticity, thus affecting shock absorption and traction.

Introducing new contaminants: Washing with water may turn sludge, dust, and other impurities on the guide rails into a paste, making them easier to adhere to the rollers and guide rail surfaces, thus accelerating wear.

2. Correct Maintenance Method: Inspection and Cleaning

The focus of elevator roller guide shoe maintenance is "cleaning" rather than "washing," with the aim of removing stubborn dirt that affects the normal operation of the rollers.

When is cleaning and maintenance required?

During regular maintenance: According to the maintenance plan, a comprehensive inspection is usually performed every 1-3 months.

When abnormalities occur: When the elevator operates under the following conditions, the guide shoes may need cleaning or replacement:

A noticeable "clunking" sound, friction sound, or vibration.

The car runs unevenly, with a swaying sensation.

The car moves slightly when the doors open and close.

Who should do it?

It must be performed by a certified professional elevator maintenance personnel.

How to properly clean and maintain?

Stop and isolate: First, stop the elevator and disconnect the power supply to ensure safety.

Inspection: Maintenance personnel will first check the following:

Roller Wear: Inspect the roller surface for cracks, chips, uneven wear (deformation).

Bearing Condition: Manually rotate the roller to check for smooth, unobstructed, and noiseless rotation.

Guide Rail Cleanliness: Check the guide rail working surface for hardened sludge, rust, or other stubborn dirt.

Professional Cleaning: Use a dry brush and vacuum cleaner to remove loose dust and debris from the rollers and guide rails.

For stubborn sludge and dirt, use a lint-free cloth dampened with a small amount of anhydrous alcohol or a specialized cleaner to wipe it. Do not use solvents such as machine oil or gasoline.

After cleaning, ensure all parts are completely dry

Lubrication and Adjustment: The guide shoe rollers themselves are lubrication-free. However, if the guide shoe holder has a lubrication cup for sliding guide shoes, check the oil level.

Check the alignment of the guide shoes and spring pressure to ensure good contact between the rollers and the guide rail working surfaces.

Replacement: If the problem persists after cleaning, or if the roller wear exceeds the allowable range (usually indicated by wear marks), the roller guide shoe must be replaced immediately.

English

English 中文简体

中文简体