Escalator rollers (often called "step rollers" or "traveling rollers") are crucial operating components in the entire escalator system. Their role goes far beyond simply "rolling," directly affecting the smoothness of the escalator's operation, passenger comfort, and safety.

The main specific functions of escalator rollers are as follows:

Content

1. Support and Load Bearing

This is the most fundamental function. The escalator rollers directly bear the entire weight of each step, along with the passengers and goods on it. They transfer this load to the guide rails, ultimately distributing it across the escalator's main structure.

2. Guiding and Direction

The rollers do not roll on a flat surface but rather along pre-set guide rails. These guide rails determine the path of the steps:

Upper Level Section (Entry/Exit Zone): The rollers guide the steps to remain level, facilitating smooth boarding and alighting for passengers.

Incline Section: The rollers run along inclined guide rails, forming the escalator's ramp.

Lower Level Section: Also maintains a level position.

Rotating Section: At the top and bottom of the escalator, rollers run along complex curved guide rails, completing the cyclical rotation of the steps.

Without the precise guidance of the rollers, the steps cannot form a stable, circulating "staircase."

3. Ensuring Smooth Operation and Vibration Reduction

High-quality escalator rollers are typically made of engineering plastics such as nylon and polyurethane, and contain precision bearings. This structure serves to reduce vibration and noise.

Vibration Reduction: When steps pass over guide rail joints or slightly uneven areas, the elastic outer ring of the rollers absorbs the impact, preventing severe jolts.

Noise Reduction: They effectively reduce noise generated by direct metal-to-metal contact and collisions, ensuring quiet escalator operation.

4. Maintaining Step Level

This is achieved through the coordinated work of the main wheels and auxiliary wheels (or axle wheels). The main wheels are usually located on the step chain, responsible for primary traction and load-bearing; while the auxiliary wheels are installed on both sides of the steps.

The auxiliary rollers run along specialized guide rails. Their key function, during inclined sections, is to force the steps to remain level through the geometric design of the guide rails. This ensures that passengers' feet are firmly planted on the steps, preventing tilting with the angle.

5. Impact on Ride Comfort

The ultimate result of all these functions is ride comfort. Severely worn, damaged, or poorly lubricated rollers can cause:

Severe vibration and bumps

Extreme friction and noise (a "rumbling" sound)

Step shaking or instability

6. Common Types and Locations of Rollers

Typically, a single step will have multiple sets of rollers:

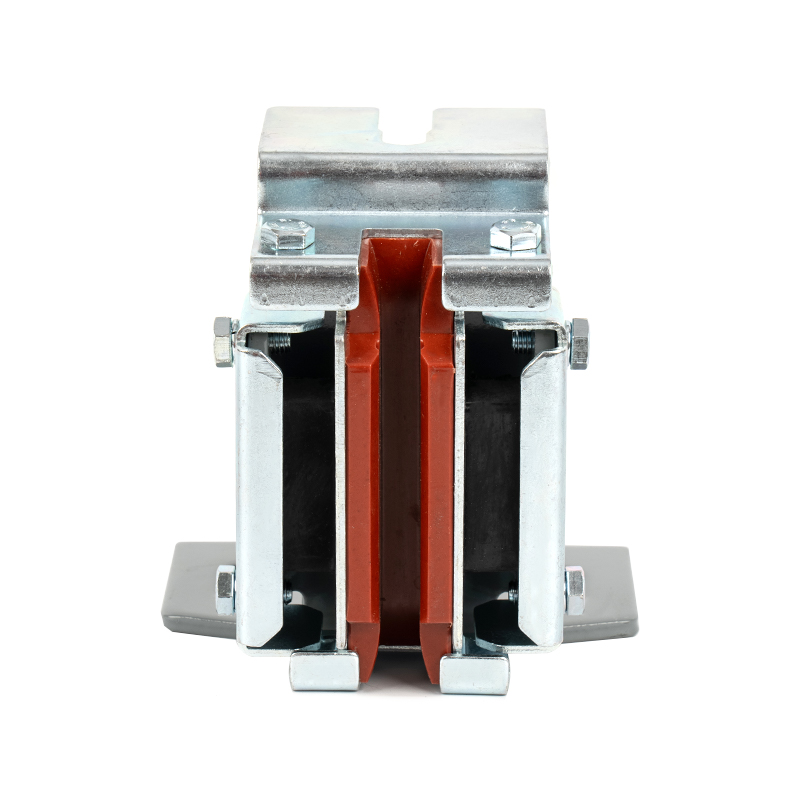

Main Roller/Traction Roller: A large wheel mounted on the axle of the step chain, it is the main wheel driving the step.

Auxiliary Rollers/Axle Rollers: Small wheels mounted on the sides of the step, primarily responsible for guiding and maintaining the step's levelness.

Anti-deviation Rollers: Sometimes additional lateral guide rollers are installed to prevent the step from shifting left or right during operation.

English

English 中文简体

中文简体