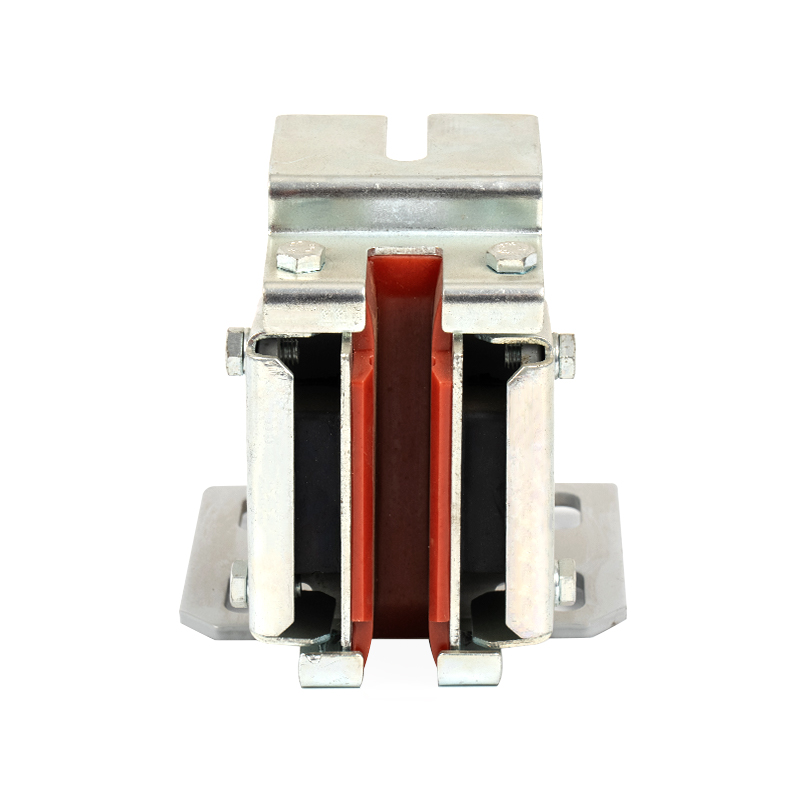

The elevator oil cup (also called "guide rail oil cup" or "lubricating oil cup") is an important component of the elevator traction system and guide rail lubrication system. It is responsible for storing and transporting lubricating oil to ensure smooth operation of the elevator. If the oil cup is damaged or fails, it may lead to insufficient lubrication, accelerated component wear, and even cause elevator failure.

1. When does the elevator oil cup need to be replaced?

(1). Physical damage to the oil cup

Cracks or breakage: Cracks in the oil cup shell will cause lubricating oil leakage and must be replaced immediately.

Aging of the seal ring: If the oil cup is not sealed tightly and lubricating oil leaks, the oil cup or seal ring needs to be replaced.

Deformation of the oil cup: Deformation due to external force affects normal oil supply.

(2). Lubricating oil contamination or deterioration

Oil is turbid and black: The lubricating oil is mixed with metal debris or dust, indicating that the oil cup is contaminated. The oil cup needs to be replaced and new oil needs to be replaced.

Abnormal reduction in oil volume: If the oil volume in the oil cup drops too quickly (abnormal consumption), it may be leakage or volatilization. Check whether the oil cup is invalid.

(3). Abnormal operation of the elevator

Abnormal noise from the guide rail or traction motor: Insufficient lubrication will cause metal friction sound, which may be caused by poor oil supply to the oil cup.

The elevator shakes or runs unsteadily: Failure of the lubrication system may affect the stability of the elevator operation.

(4). Expiration of the maintenance period

Ordinary lubricating oil cup: Check and replace every 1~2 years (depending on the frequency of use).

High-load elevators (such as shopping malls and office buildings): It is recommended to check once every 6~12 months and replace if necessary.

2. How to determine whether the oil cup needs to be replaced?

(1). Visual inspection

Check whether the oil cup has cracks, oil leakage, or deformation.

Observe whether the lubricating oil is clear. If it turns black or has impurities, the oil cup and oil need to be replaced.

(2). Manual test

Gently shake the oil cup by hand to check whether it is loose or leaking.

Check whether the oil outlet of the oil cup is blocked (you can use a fine needle to clean it. If it is still blocked, it needs to be replaced). (3). Professional testing

Use a lubricating oil tester to analyze the oil quality (applicable to large elevator systems).

Maintenance personnel can monitor whether the lubrication system pressure is normal through the elevator control system.

3. Precautions for replacing the oil cup

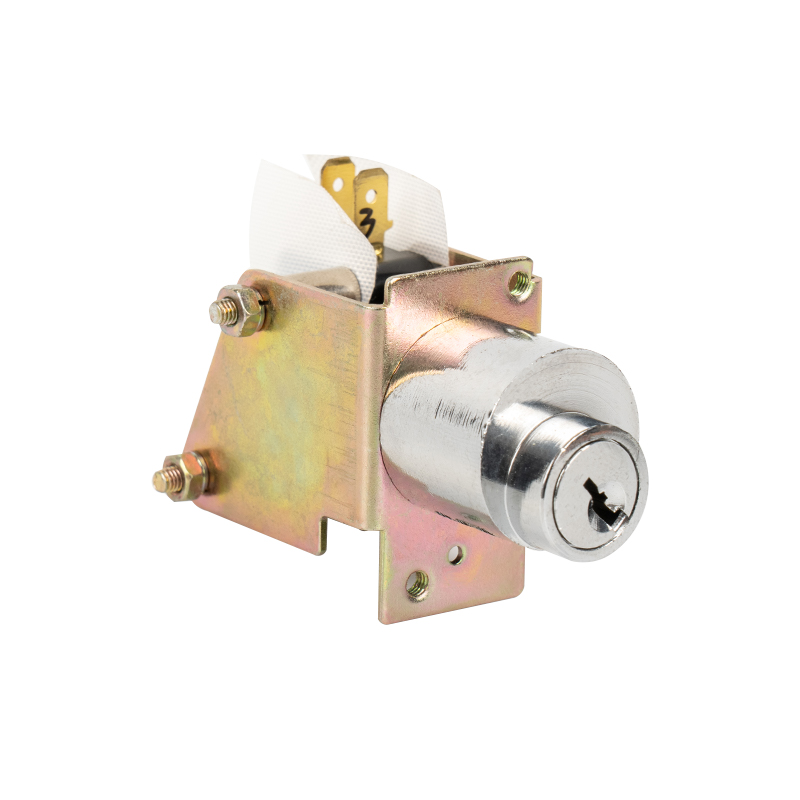

Select a matching model: The oil cup specifications of different brands of elevators are different. You must use the original or compatible model.

Thoroughly clean the oil circuit: When replacing the oil cup, clean the oil pipe and lubrication points to prevent residual impurities from affecting the new oil.

Use qualified lubricating oil: Different elevators have different requirements for lubricating oil viscosity.

Test operation after replacement: After replacing the oil cup, manually test the lubrication system and observe whether the elevator runs smoothly.

Elevator oil cup replacement standards:

| Situation | Replacement Required |

| Oil cup cracked, deformed, or leaking | Replace immediately |

| Lubricating oil is black or contains impurities | Replace the oil cup and oil change |

| Elevator experiences unusual noise or vibration during operation | Check the oil cup and replace if necessary |

| Maintenance period expired (1-2 years) | Replacement Recommended |

English

English 中文简体

中文简体