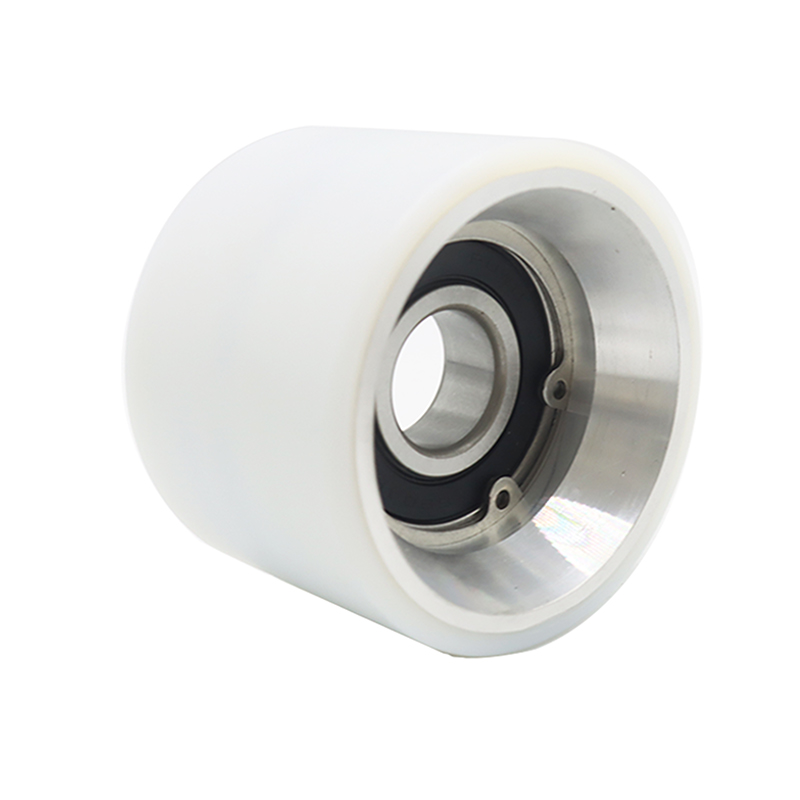

As the core component of elevator safety monitoring, the Elevator Speed Measuring Wheel not only bears the task of real-time monitoring of the elevator's running speed, but also becomes the guarantee of the stable operation of the elevator through the combination of material selection and engineering design.

The structure of the elevator speed measuring wheel combines the dual advantages of the iron wheel core and the nylon outer ring. With its high strength and high hardness, the iron wheel core can easily cope with the load generated when the elevator is running at high speed, and can still maintain structural stability during frequent start-stop or long-term high-load operation. The nylon material wrapped in the outer layer of the iron core improves the wear resistance and lubricity of the speed measuring wheel. This combination not only reduces the friction loss between the roller and the track, but also resists the erosion of moisture, oil and chemical corrosion, effectively extending the service life of the speed measuring wheel.

The size design of 80 mm outer diameter and 30 mm height makes the speed measuring wheel suitable for a variety of elevator models, ensuring the stability of the speed measuring wheel when rotating at high speed. The elevator speed wheel can also provide dynamic operating parameters for the elevator safety system by capturing the rotation frequency of the roller in real time, thereby triggering the overspeed protection mechanism to prevent potential risks such as sliding and hitting the top. The pressing process of the iron core and the nylon outer ring not only ensures the structural strength of the component, but also enables rapid disassembly and assembly through standardized interfaces. Maintenance personnel can replace worn parts without complex tools. Efficient maintenance not only reduces operating costs, but also adds a layer of protection for passenger safety by reducing potential faults.

English

English 中文简体

中文简体